Lesson 4: Safety While Working with Large Machines

Safety While Working with Large Machines

WORD LIST

| adjustment |

the act of changing the way a machine runs. Example: some adjustments to a lathe might be: replacing the cutting tool, increasing the speed, or changing the angle of the cut. |

| to be in charge |

to be the boss, to be responsible for. Example: when Carlos and Juan work together at the lathe, Carlos is in charge of turning it on and off. |

| belt |

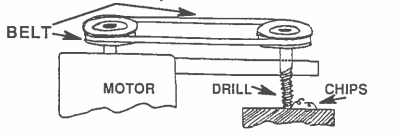

a circle of strong rubber or plastic that is used to drive the parts of a machine with the help of a motor. Example: the drill was driven with a belt and a motor.

|

| to brush away |

to remove small particles with a wiping motion of a brush. Example: Pete used a brush to brush away the chips around the drill. |

| to check |

to look carefully to make sure everything is correct. Example: the instructor will check how you set up the work, before you begin the job. |

| cord |

an electrical wire that carries electricity to the motor. Example: he pulled the electrical cord out of the wall to disconnect the electricity. |

| depth |

is a measurement of how deep something is. Example: Oscar checked the depth of the hold he was drilling. |

| to flow |

to run through a pipe (liquid) or a wire (electricity). Example: the water flowed through the pipe into the river. |

| guard |

a piece of metal or plastic on a machine; it is used as a protection to prevent a worker from getting injured. Example: the guard on a machine will keep fingers out of gears or prevent machining liquids from spraying onto the skin. |

|

power |

the electricity that runs the motors that run the machines. Example: this cord has been cut! We have no power for our machines! |

|

precaution |

is anything you do to look ahead and watch out for unsafe conditions. Example: it is a good precaution to turn of the motor, if you are going to measure the work-piece. |

|

to repair |

to fix something that is broken or is not running correctly. Example: large machines shops sometimes hire a specialist whose job is to go around and repair machines that have problems. |

|

to replace |

to take away a broken or worn-out part and put in a new one. Example: often it is less expensive to replace a part instead of trying to repair it. |

|

speed |

how fast a machine is running or turning. Example: the speed of the lathe is often measured in RPM’s (revolutions per minute, how many times the part turns around in a minute). |

| to stand out of the way |

to stand at a distance from where there is a danger. Example: Jorge always stands out of the way of blades and moving parts when he turns on his lathe. |

Vocabulary Exercise

SAFETY WHILE WORKING WITH LARGE MACHINES

Much of a machinist’s time will be spent operating large, powerful machines like lathes, mills, drill presses and surface grinders. All of these machines have electric motors that turn gears and belts. These gears and belts give power to the tools that cut, drill, or grind. There are other controls on the machines that allow the machinist to control the speed and depth of the cutting, drilling, and grinding.

Much of a machinist’s time will be spent operating large, powerful machines like lathes, mills, drill presses and surface grinders. All of these machines have electric motors that turn gears and belts. These gears and belts give power to the tools that cut, drill, or grind. There are other controls on the machines that allow the machinist to control the speed and depth of the cutting, drilling, and grinding.

Each machine has parts that need replacing from time to time. A lathe will need to be sharpened, and a drill may need to have a different size boring tool. From time to time the machinist will want to look at or measure the workpiece to see if his/her work is correct. From time to time he/she will want to brush away chips or grinding dust that the machine has made.

All of the above facts require safety requirements by the machinist.

1.) When the machine motors are running, be sure to stay away from the moving gears and belts. That is one of the reasons why you should not wear jewelry, ties, scarves, long sleeves, and long hair – all these things can get caught in the machine, and you could be pulled into the machine. Even if you don’t wear jewelry, it’s still possible to get limbs (hands, feet, arms, and legs) caught in the machines, if you are not careful.

2.) The machine is not as dangerous when the power is off, so when you want to do any of the following things, you should turn off the motor of the machine:

- If you wish to look at, or measure, a workpiece, turn off the motor.

- If you wish to brush away chips or dust, turn off the motor.

- If you want to examine or replace a cutting tool or a drill, turn off the motor.

- If you want to make minor adjustments to the machine, the workpiece, or the motor, turn off the motor.

- If you need to repair the machine or make major adjustments, you need to pull out the power cord, or disconnect the electricity. (If you are reaching inside the machine where the gears and belts are, you do not want any possibility that the power will come on. You also want to prevent electric shock, in which electricity flows through your body).

3.) Before you turn on the power, you want to be sure that everything is secure:

- Make sure that the workpiece is tightly in place.

- Make sure that the cutting, drilling, and grinding tools are secure.

- Make sure that any protective guards (that cover dangerous parts) are secured in place.

- Make sure you are standing out of the way of moving parts.

4.) Frequently as a tool cuts through a metal workpiece, it will leave a little sharp pieces on the part near where the operation was done; these sharp pieces, called burrs, can cut fingers and hands. Sometimes these burrs are big and easy to see; at other times they are small and difficult to see.

- When a workpiece is removed from a machine, check the part for burrs and sharp edges.

- Deburr each part by grinding off those sharp pieces. (In some large machine shops, many of the parts are sent to a deburring work station where one or more people grind off the burrs).

5.) If you need to leave a machine to go ask a question, or go to the restroom, or for any other reason, TURN OFF THE MOTOR, of the machine before you leave your machine.

6.) When two students are working at one machine, only one of the students should be in charge of operating the controls, turning switches on and off, etc.

7.) Before you turn on a machine, have the instructor check to see that you have set up the work correctly.

How well did you Understand?

Print this document. Write your answers on the sheet of paper.

When you finish writing, show this paper to the teacher and talk about what you have written.

Then continue with the End-of-Lesson Questions.

End-of-Lesson Questions