Lesson 5 Milling Accessories

Pre-Reading

In Module 7, Lesson 5 we studied the accessories used in a lathe to do more jobs.

We saw that some of the accessories are for holding the workpiece (e.g., a lathe chuck) and others are for rotating the parts (e.g., a lathe dog).

In this lesson we will study some accessories that help the milling machine to do more jobs:

Some of these accessories are for holding the workpiece (e.g., a vise which is bolted to the table) and others are for holding and driving the milling cutters (e.g. an arbor or an adapter)

Let’s also remember the differences between a lathe and a milling machine:

A LATHE ROTATES THE WORK AND FEEDS A CUTTING TOOL INTO THE WORK.

A MILLING MACHINE ROTATES THE CUTTER AND FEEDS THE WORK INTO THE CUTTER.

Review Questions

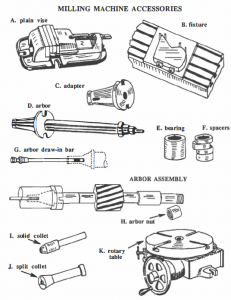

MILLING MACHINE ACCESSORIES

| 1.) conference | a meeting between people with a problem who are trying to find some answers. e.g., The supervisors and the machinists had a conference on shop safety. |

| 2.) to draw in | to pull inside, to pull something into a hole. e.g., The arbor is drawn into the spindle by the draw-in bar. |

| 3.) excessive | too much of anything. e.g., If the heat made by the cutting tool becomes excessive, the tool will wear out sooner. |

| 4.) pin | a straight piece of metal, often with a pointed end, used to hold something in place. e.g., Mona pushed three pins into holes in a sheet of metal to hold the workpiece tightly. |

| 5.) to position | to put something in a desired place. e.g., The cutter is positioned on the arbor by the use of spacers. |

| 6.) rotary motion | motion in a circle, rotation. e.g., The rotary table will turn in a circle using rotary motion. |

| 7.) suggestion | an idea, given to other persons, telling them what they might do. e.g., Gladys, I have a suggestion for you: You should try apologizing to Henry. |

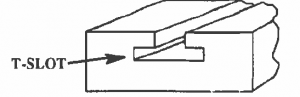

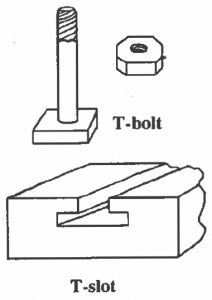

| 8.) T-slots | these grooves are cut in the shape of a Tinto the tables which hold work for milling. e.g., These T-bolts can be fitted into the table’s T-slots. |

Vocabulary practice

MILLING MACHINE ACCESSORIES

For efficiency, accuracy, and a wider variety of job, milling machines need several different attachments.

Any attachment which holds the workpiece in place on the table is very important. All such attachments depend on the T-slots cut along the length of the table. Into these slots, T-bolts can be inserted: they will project their threaded ends up above the surface of the table and can be used to attach a variety of work-holding devices.

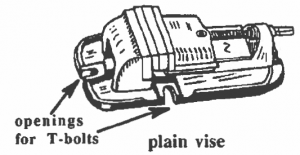

1.) Vises: Any table vise will have U-shaped spaces cut on the sides for the T-bolt ends to fit. When bolted to the table, a vise has a pair of jaws for holding the workpiece; the jaws are tightened or loosened by turning the screw or crank at the end of the vise. There are several kinds of vises:

1.) Vises: Any table vise will have U-shaped spaces cut on the sides for the T-bolt ends to fit. When bolted to the table, a vise has a pair of jaws for holding the workpiece; the jaws are tightened or loosened by turning the screw or crank at the end of the vise. There are several kinds of vises:

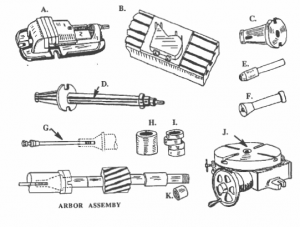

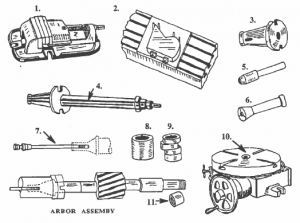

a.) Pictured here is a plain vise; it is mounted on the table with jaws either parallel or perpendicular to the length of the table.

b.) The swivel base vise is a second kind of vise; it has a round base which will rotate the vise jaws through a complete 360° tum in the horizontal plane only.

b.) The swivel base vise is a second kind of vise; it has a round base which will rotate the vise jaws through a complete 360° tum in the horizontal plane only.

c.) A third type of vise is the universal vise; it rotates 360° in the horizontal plane; it also rotates 90° in the vertical plane, so a wide variety of angles are possible.

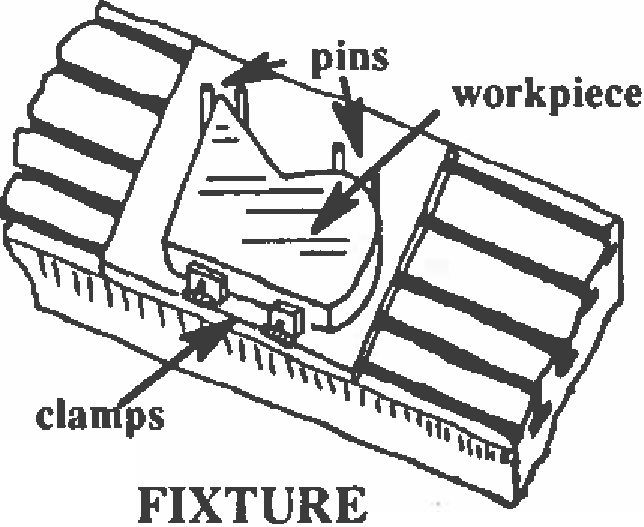

2.) Fixtures: Another frequently used work-holding device is the fixture; fixtures are usesful for repetitive work when a large number of identical parts are being made or when there is an irrregularly-shaped part that will not fit easily into a vise.

In the picture, an irregularly-shaped work piece is held in position by four pins and two clamps. The clamps can be quickly removed and an identical new workpiece can be placed in position and securely held. The major precaution is to clear the chips away from the fixture before a new workpiece is put in place.

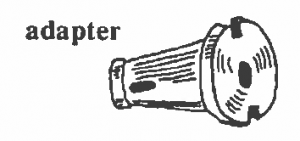

3.) Adapters:

An adapter. as we have seen, is made to hold a variety of cutting tools, such as the shell end mill or the flycutter. The adapter is then fitted into the Morse taper of the mill’s spindle. Adapters can be used on either horizontal or vertical mills.

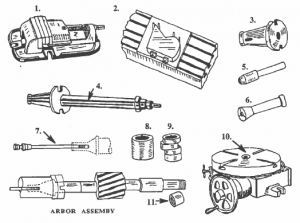

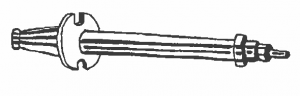

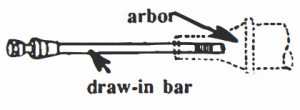

4.) Arbors: An arbor is needed for the horizontal milling machine. It is a strong, solid steel cylinder onto which a milling cutter or milling cutters are placed.

The cutter or cutters are held in place by keys which fit in the keyways and by the spacers which pinch in on the sides of the cutter and position the cutter in the desired place along the arbor. The key prevents the cutter from turning on the arbor.

The tapered end of the arbor is pulled into the tapered spindle by the use of a draw-in bar which is run through the back of the mill into the spindle. The draw-in bar is screwed into the arbor about one inch. The arbor is secured with a nut at the other end of the arbor beyond the draw-in bar last arbor support.

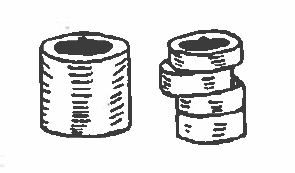

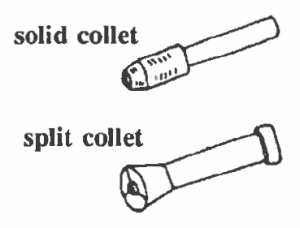

5.) Collets: These tools will hold tapered-shank cutting tools of various sizes. Drills and end mills can be held in a collet. The collet will fit in the milling machine’s spindle or in the vertical milling attachment.

The collets are of two kinds: either the solid collet or the split collet. In both kinds, the shank of the cutter is held in place by fitting into the tapered hole of the collet.

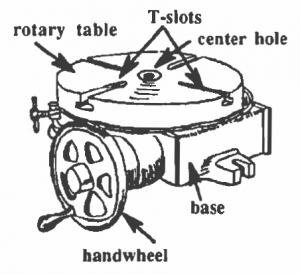

6.) Rotary Table: This table has a base which is bolted to the milling machine table by means of T-bolts. The rotary table itself has T-slots which are cut into its top and make it easy to clamp a workpiece to the table. The rotary table has a hole in the center into which a test plug can be fitted; this makes it easy to center the table with the spindle of a vertical mill.

The rotary table permits the machinist to cut radii from the center, to make circular grooves, and to drill or bore holes in a circular pattern. This is possible because of the rotary motion (motion in a circle) of the rotary table which is added to the vertical and horizontal feeds of the milling table. This rotary feed can be done by hand (with a handwheel as in the picture above) or through an automatic power feed.

The rotary table permits the machinist to cut radii from the center, to make circular grooves, and to drill or bore holes in a circular pattern. This is possible because of the rotary motion (motion in a circle) of the rotary table which is added to the vertical and horizontal feeds of the milling table. This rotary feed can be done by hand (with a handwheel as in the picture above) or through an automatic power feed.

Student Practice Sheet H5P toooooollllll???????? Ex. 8.59

Exercise 1:Follow the directions below:

Draw a circle around any parts which can be mounted on an arbor:

SPACERS FIXTURE BEARING BUSHING SOLID COLLET

ANGULAR MIl.LING CUTTER MULTI-FLUTED END MILL

Draw a line under any parts which help hold the arbor in place:

DRAW-IN BAR BEARING BUSHING PLAIN VISE ARBOR NUT

ARBOR SUPPORT SPLIT COLLET MORRIS TAPER

Draw a box around any cutting tools which will fit into a collet.

TWO-FLUTED END MILL FORMED CUTTER METAL SLITTING SAW WOODRUFF KEYSEAT CUTTER DOVETAIL CUTTER T-SLOT CUTTER SIDE-MILLING CUTTER WITH STAGGERED TEETH

Comprehension Check

Practice Conversation

Situation: Two machinists, Roberto and Lee, are talking about their work.

Roberto: Lee, I had a problem this morning while milling some parts. I had to stop twice and change cutters, because they were getting dull.

Lee: Well, Roberto, many times the quick dulling of a cutter is due to excessive heat. When the steel of the cutter heats up it loses some of its hardness, the wear is greater, the cutting is less efficient, and then even more heat builds up.

Roberto: What can I do to prevent that?

Lee: To cut down on heat, you need to use the correct speed and feed rates. You have to check if you’re using the right coolant and that the cutting area is getting plenty of coolant on it.

Roberto: What if it keeps happening?

Lee: I know you’re using the cutters described in the blueprint and the production notes, but sometimes the engineers make mistakes. If it keeps happening and it’s slowing you down, you might tell the supervisor and have a conference with one of the engineers.

Roberto: Hey, thanks for the advice. I’m going to try some of your suggestions.

Lee: That’s okay, Roberto. I hope you have a good afternoon.

Accessory Names

Matching

Spelling Practice

Accessory Identification