Lesson 6 Milling Operations

Pre-Reading / Scanning

Look through the information below and match the names of the milling machine operations shown in these drawings.

Word List

| 1.) advantage | a benefit or good which comes from doing something one way instead of another. e.g., The main advantage of driving over walking is the speed of travel. |

| 2.) to aim | to point in a certain direction. e.g., The sheriff aimed his gun the bandit. |

| 3.) to anchor | o hold something securely in one place. e.g., Daniel anchored his car on the hillside by pulling on his brakes. |

| 4.) to all | to even the smallest degree. e.g., If you are at all sleepy, please get off the highway and sleep. |

| 5.) to climb | to go up by using a series of steps. e.g., In climb milling, the cutter teeth cut downward, climbing one tooth at a time. |

| 6.) conventional | according to expectations; what is commonly done. e.g., A conventional way of doing something is what most people do. |

| 7.) gang | a set of tools (or cutters) arranged to work together. e.g., Gang milling uses several cutters to make many cuts with one motion of the table. |

| 8.) to index | to divide the circumference of a circle into equal parts. e.g., To make a gear, the circumference of the gear must be indexed. |

| 9.) operator | someone who runs a certain kind of machine. e.g., Mary has been a mill operator for several years. |

| 10.) range | the complete number of possible actions something can do. e.g., A milling machine has a large range of operations which it can do. |

| 11.) repetitive | doing something over and over again. e.g., Making coat hangers a very repetitive job. |

| 12.) shallow | not deep. e.g., Shallow water is safer for small children to swim in than in deep water. |

| 13.) steady | fixed; not shaking, moving, or rattling. e.g., The arbor support hold the arbor and the cutter in a steady position. |

| 14.) to straddle | to be on both sides of something, like putting a leg on both the right and left sides. e.g., The cowboy straddled the fence, as he watched the sun go down. |

| 15.) tip | a suggestion; good advise which will help a person in the future. e.g., Abdul gave me a tip that I should be nice to the boss’s daughter. |

Vocabulary Practice

MILLING MACHINE OPERATIONS

A good machinist, with practice, will come to know and use the full range of operations that the milling machine can do. We can begin that growth of knowledge by looking at some basic operations of the mill.

1.) Some general ideas on operating the mill:

A.) Feeding the work into the mill:

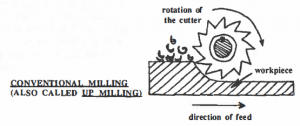

The usual method of milling is to feed the work against the cutter’s direction of rotation; this is called conventional milling or up. milling (because the cutting teeth are heading up into the work as they cut the workpiece).

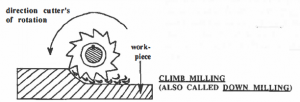

A second way of feeding work into the cutter is to feed the work piece in the same direction as the rotation direction cutter’s of the cutter; in this method the cutting teeth will be coming down into the work as they cut the workpiece; this type of cutting is called climb milling or down milling.

direction of feed

Conventional milling is called “conventional” because it is used for most jobs. Climb milling is less frequently used, but it does have some advantages: it requires less power, it produces a better finished surface, it is easier to do hard-to hold work.

B.) Depth of cut: The machinist must make decisions about how deep the milling cuts will be. Usually there will be two cuts, as in lathe work: (1) a roughing cut which is deep and with a heavy feed and (2) a finishing cut with a finer feed and a shallow cut.

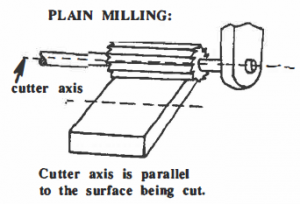

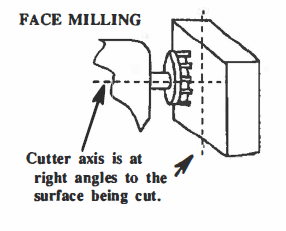

C.) Basic kinds of milling: Most operations on a horizontal mill will either be plain milling or face milling.

Plain milling happens when the surface which is cut lies parallel to the axis of the cutter.

Face milling is where the surface which is cut lies at right angles to the axis of the cutter.

We saw examples of these kinds of milling in the last lesson.

2.) Special operations gf the mill: There are several other milling operations that we should study:

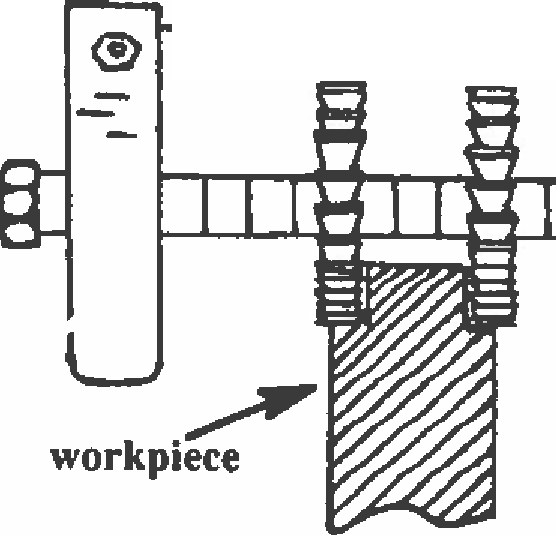

A.) Straddle Milling:

This kind of milling uses two side milling cutters to machine both sides of a workpiece with one traverse of the table. The machinist must be sure to carefully space the distance between the two cutters by the use of spacers of the correct size.

One example of straddle milling is machining the flat opposite sides on bolt heads. Staggered tooth side milling cutters work best for this.

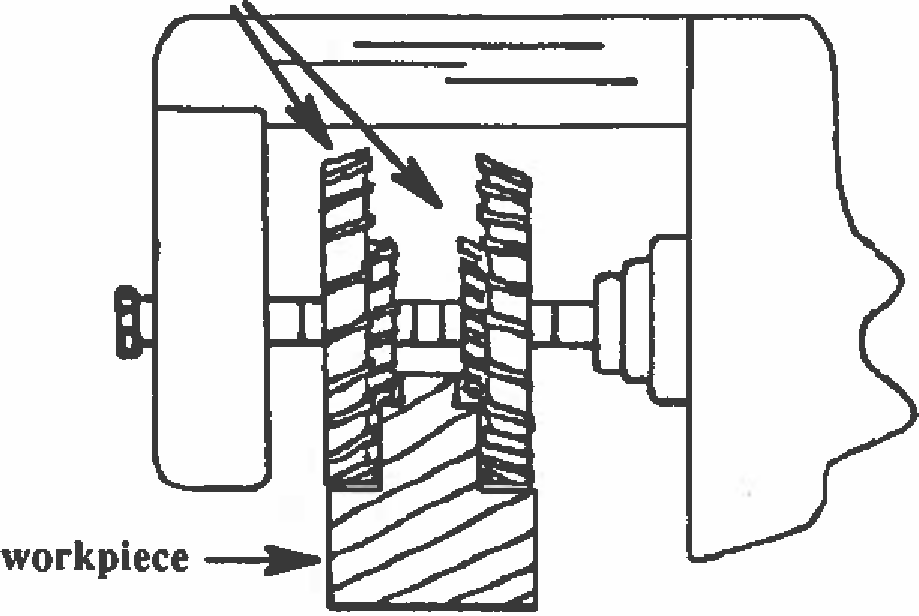

B.) Gang Milling:

This kind of milling uses a cutters group of cutters on an arbor. In our picture we see four cutters being used to make a certain shape in just one pass of the table. This is very useful when you are repetitively making a mountedlarge number of identical parts.

This kind of milling uses a cutters group of cutters on an arbor. In our picture we see four cutters being used to make a certain shape in just one pass of the table. This is very useful when you are repetitively making a mountedlarge number of identical parts.

For gang milling it is possible to mount a variety of plain and side milling cutters on the arbor, but results will be better if the cutters have approximately the same number of teeth on them. It is well to use a good supply of cutting fluid in this operation.

C.) Sawing: The slitting saw can be used for cutting off pieces of work or for cutting deep slots. Because the blade is so thin and has such a large diatmeter relative to its thickness, the blade can easily break under stress; therefore, there is no Woodruff key used to hold the sawing blade on the arbor. If it comes under much pressure, it is then free to simply tum on the arbor without breaking. Three good suggestions for using the saw are:

-

- run the saw at lower speeds,

- keep the saw well sharpened, and

- use climb milling to avoid a feed that goes opposite the direction of the cutter rotation–climb milling will cause less friction.

D.) Indexing: Another special milling operation, called indexing or dividing, is needed when the machinist wants to divide the circumference of a circle into equal parts, as, for example when he/she wants to know how to space the cutting of a certain number of teeth on the periphery of a gear. Special equipment is needed for such an operation.

E.) Other operations: We have already seen some of the operations of the vertical mill, especially the milling of keyseats, dovetails, and T-slots.

Matching

Situation: Ross, a new machinist, is talking with Mary who has worked as a mill operator for three years.

Ross: Mary, I know you’ve been a machinist for several years. What kind of tips can you give a person like me who’s just learning about milling operations?

Mary: Well, Number One is to take a good look at the cutting edge of any cutter you’re going to use. If the cutter is at all dull, sharpen it!

Ross: What else?

Mary: Always make sure that the work is properly secured to the table, and aim the direction of the cut toward where the work is anchored well.

Ross: Those are good suggestions. What other tips do you have?

Mary: Well, there’s some little things to check: Make sure the cutter is rotating in the right direction for the cutting teeth to cut. Use plenty of cutting fluid. Mount end mills with as short a shank as possible–they’ll be more solid–and put the arbor supports on as close to the cutter as possible–the cutter will be steadier.

Ross: It sounds like a lot of these tips have safety as one of their main reasons.

Mary: Yes, that’s true. You want to be safe at all times. Your hands, your eyes, your life–they can’t be replaced. Also, if you follow these suggestions your production will go up. There’s nothing slows you down like a tool breakdown. Ten minutes for sharpening is worth it.