Lesson 9: Saws, Drills, and Grinders

Word List: Set A

1. replaceable

– when a part wears out, you can put in a new one.

Example: The blade on a hacksaw is replaceable.

2. frame – strong metal pieces for holding something in place.

Example: A hacksaw has a metal frame to hold a saw’s blade.

3. spray – to send a cloud of small liquid particles onto a workpiece.

Example: Tran Nyugen sprayed paint onto the chair he had just made.

4. coolant – usually a liquid with chemicals, used to lessen or prevent a build-up of heat. Example: Mario bought a large bottle of coolant from the machinist’s supply store.

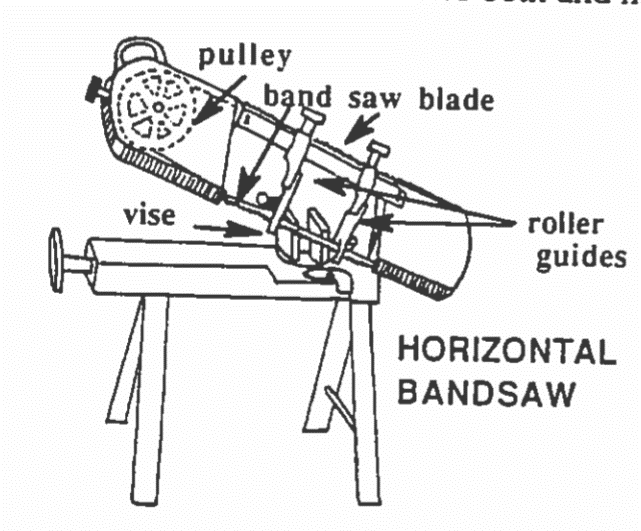

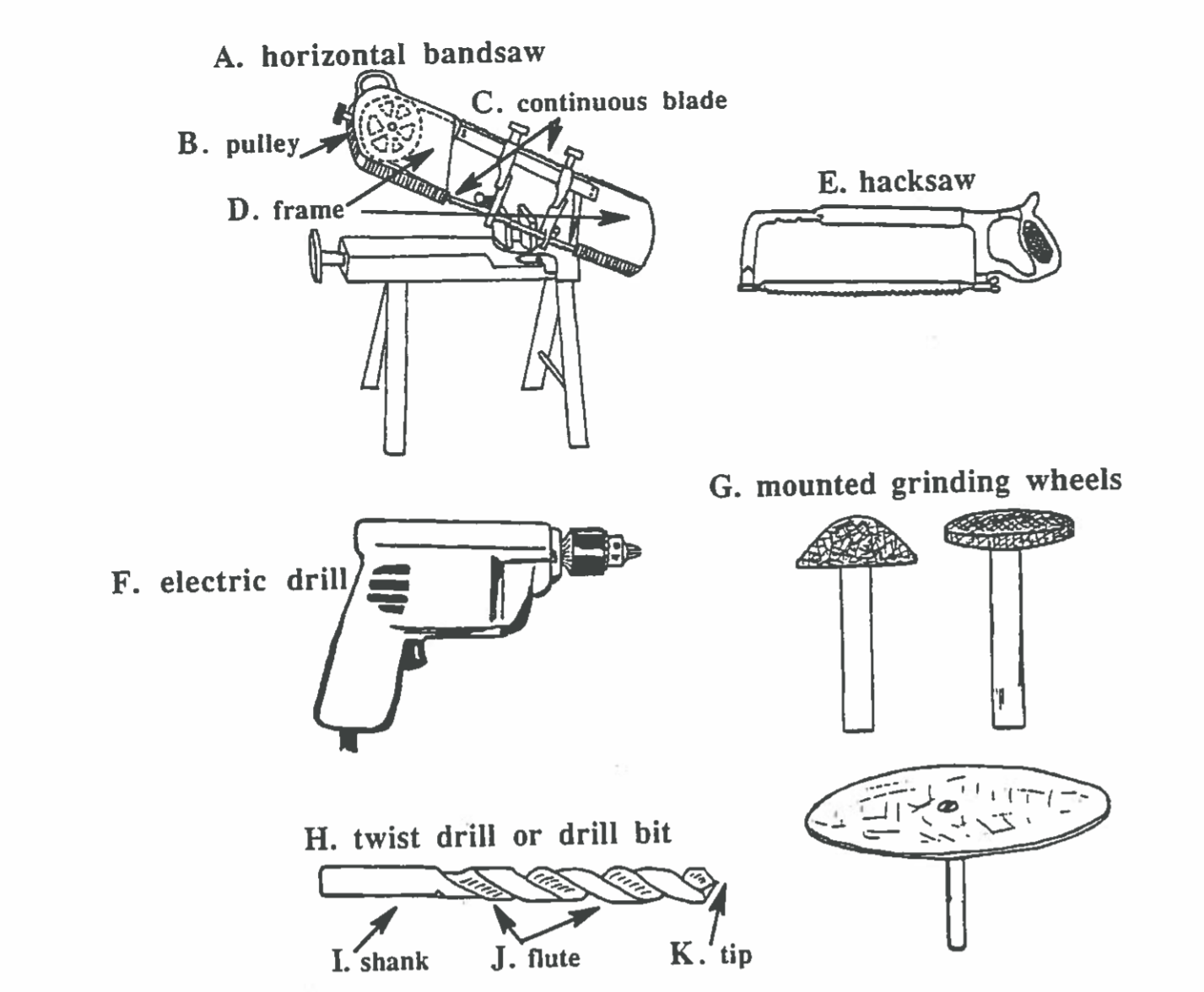

5. pulley – a round piece of metal with a continuous groove cut into the edge of a belt or band to run on.

Example: The bandsaw blade runs around two pulleys inside a frame.

6. horizontal – parallel to the ground, flat and even, going from side to side.

Example: This saw cuts in a horizontal direction, from side to side of the workpiece.

7. vertical – up and down, going straight up and coming straight down.

Example: Line A is horizontal and line B is vertical.

8. continuous – unbroken, in one piece, with no end.

Example: A circle is a continuous line, because it has no end point.

9. band – a continuous belt which goes around two pulleys.

Example: The blade of a bandsaw is one continuous band for cutting.

10. flexible – able to bend without breaking.

Example: A bandsaw blade is made of flexible steel.

Vocabulary Practice for Set A

Word List: Set B

1. cart – a small vehicle with wheels, which can be pushed around by hand.

Example: In Tijuana I have seen vendors pushing food carts filled with fruit, ice cream, and other foods.

2. mounted – fastened in the proper place.

Example: The fire extinguisher was mounted on the wall in the classroom.

3. notch – a piece cut out of an edge or surface.

Example: The wooden bench had many notches cut into it by citizens of the town.

4. roller – a cylinder of metal, wood, rubber, etc. over which something is rolled for easy movement.

Example: The Mail Service uses a line of rollers to move big packages around the post office.

5. contour – the outside lines that from the shape of something.

Example: The contour of this gear is a circle with notches cut into the edge.

6. irregular – not going in a straight line, but turning in different directions.

Example: A vertical band saw can cut irregular shapes from a piece of metal.

7. angular – adjective form of the word angle (a shape made by two straight lines that meet at a point).

Example: A band saw will do angular cutting.

8. feed – to run forward in a continuous way, like rough stock running smoothly through a bandsaw.

Example: Alonzo feeds the rough stock into the bandsaw blade.

9. bind – to get stuck so that there is little or no movement.

Example: When a saw blade heats up the metal expands and the blade will bind in the workplace.

10. coat – a covering of liquid over something.

Example: Manuel put another coat of paint on the outside of his house.

Vocabulary Practice for Set B

SAWS, DRILLS AND GRINDERS

1. Kind of Saws

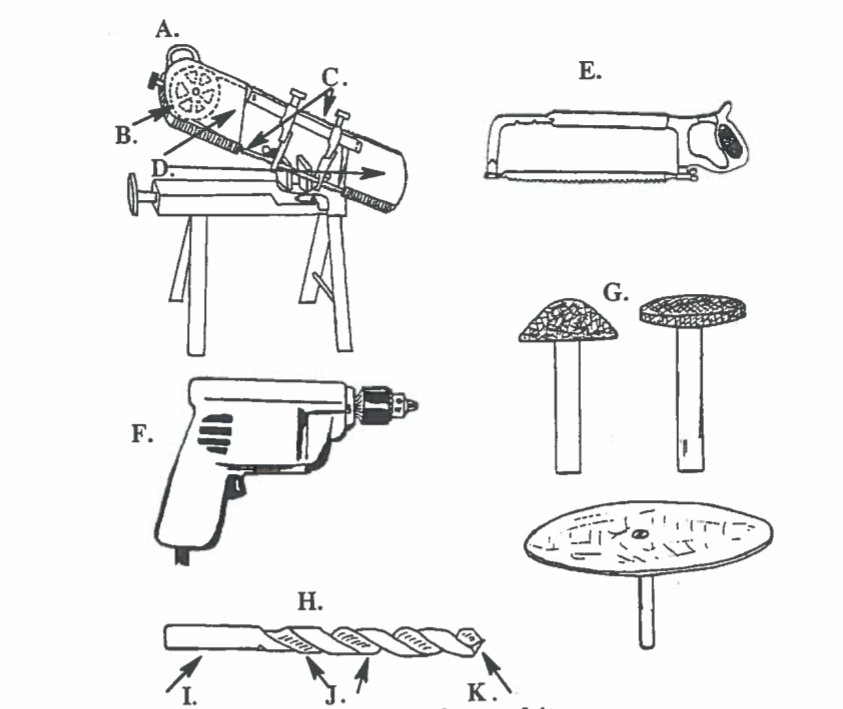

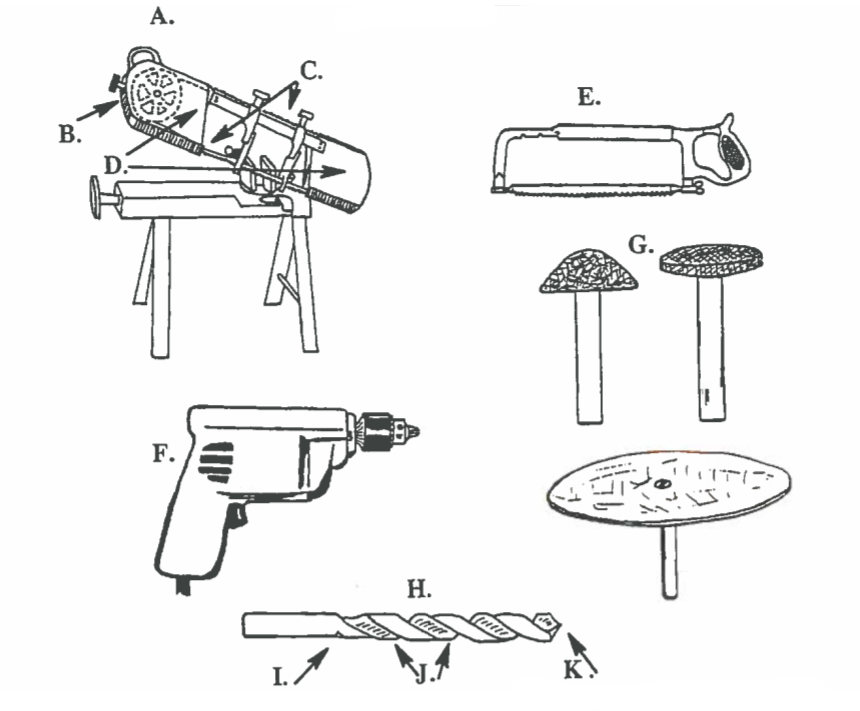

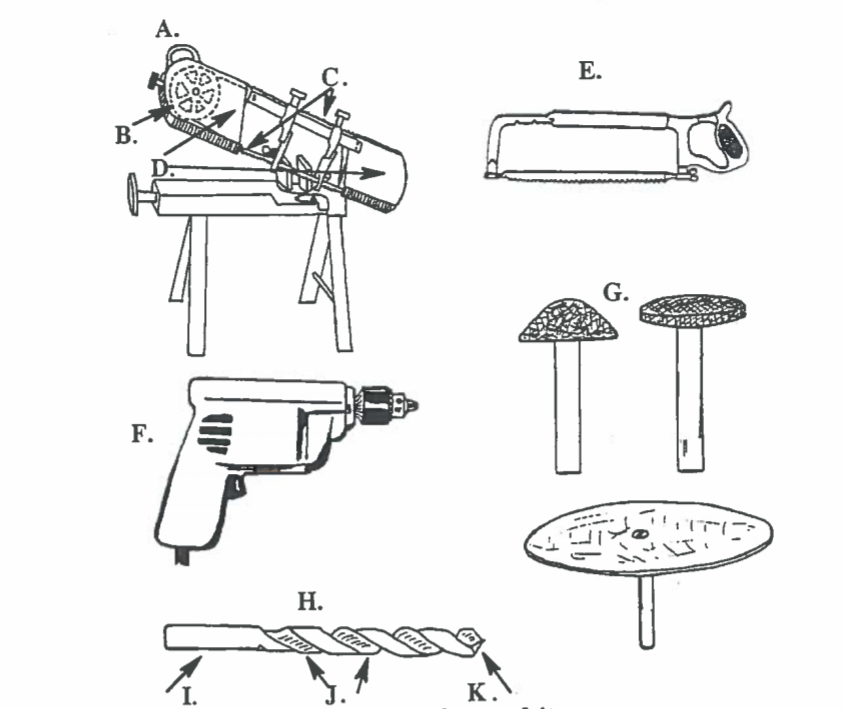

Many times the machinist will want to saw material from rough stock or from a workpiece. For example, it may be easier and quicker to cut a piece out with a saw, instead of cutting or drilling it out one chip at a time. In that case the machinist will use a saw. There are many kinds of saws used by machinsts.a. The portable hand hacksaw: This saw has a replaceable blade held in a frame; it also had a handle. The teeth of the blade point forward, and the saw only cuts during the forward stroke (like a file) when pressure is applied.b. The power hacksaw: This saw also has a frame and a replaceable blade, but is powered by a motor and can be spray coolant on the blade and workpiece during the cutting. This saw is usually too heavy to carry, but it sits on a cart with wheels and can be moved around on the shop floor.c. The horizontal bandsaw: It is a power saw (uses a motor) that cuts in one direction using a blade which is a continuous band (circle) of flexible steel. The band is like a belt around someone’s pants; it is fitted around the pulleys, one at each end of the frame. The blade is kept running true (straight) by a pair of roller guides. It is called a horizontal bandsaw, because the saw blade band usually runs in a horizontal position (parallel to the floor). Below, we have one of the pulleys inside the frame; there is another one at the saw. The bandsaw blade circles both and moves in a continuous path.

|

There is also a vertical band saws which have blades running continuously in a vertical direction (up or down). The horizontal and vertical saws are usually mounted on heavy bases and are usually mounted on heavy bases and are not portable. There saws can be seen as an introduction to the non-portable, heavy machine tools we will study in later chapters. |

More “Saws, Drills, and Grinders”

2. Kinds of Sawing:

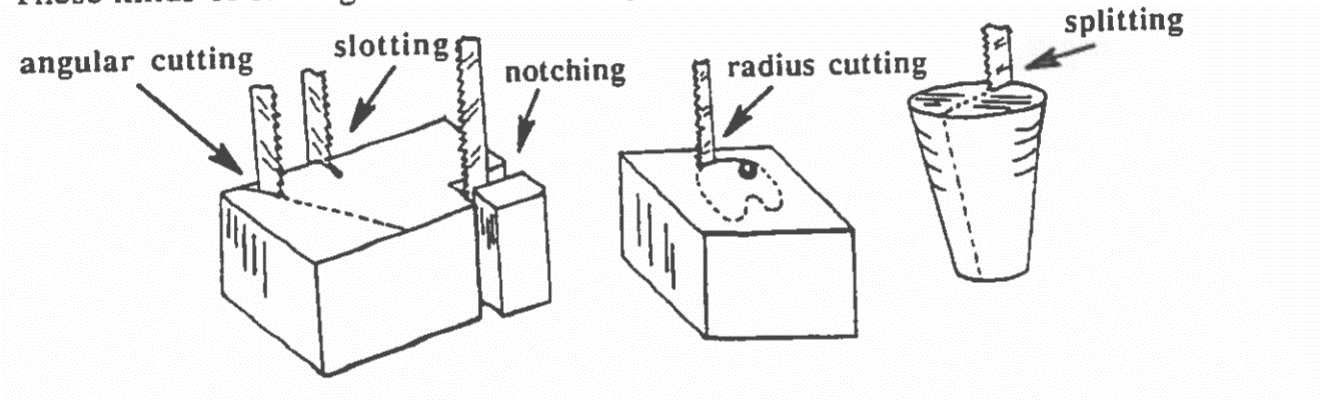

There are many different kinds of sawing that can be done with these saws:

- Notching: To cut a part of the material away from a workpiece in one larger piece, instead of one chip at a time.

- Slotting: To cut a slot in a workpiece with a saw.

- Splitting: To cut something into two or more pieces.

- Radius Cutting: To cut out some irregular shape by cutting along contour lines (shape lines) on the layout.

- Angular Cutting: To cut a workpiece by clamping it and feeding it through a power saw at an angle.

These kinds of sawing are shown in the pictures below:

When sawing in any of these ways, the job will be easier, if the machinist uses coolant to keep the saw blade and the workpiece from heating up and the saw-blade from binding (getting stuck) in the work. Some of the power saws spray coolant on the work and the blade. When using a hand hacksaw or a saw without the spray, the blade can be coated with coolant before the job begins.

Word List: Set C

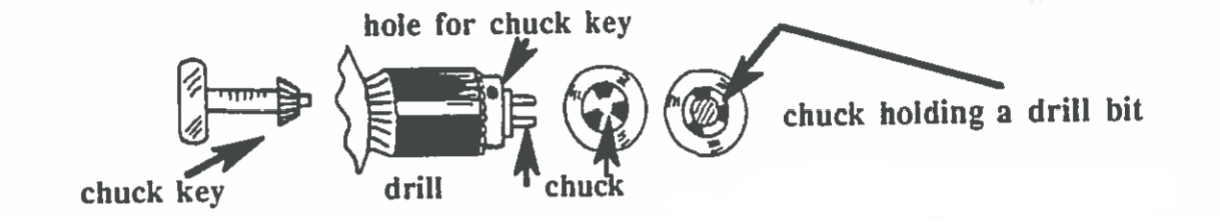

1. chuck – a clamp with jaws which can be tightened with a key. Example: A drill chuck holds the drill bit; a lathe chuck holds a piece of rotating round stock.

2. shank – the long, narrow shaft between the holding part (the chuck) and the cutting part (the tip and the flutes).

Example: The shank of the drill fits into the chuck.

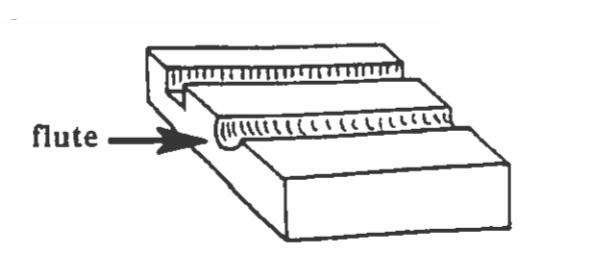

3. flute – a rounded groove cut into the surface of something.

Example: It is possible to have more than one flute on a drill bit.

4. twist – to move in a curved or irregular path, especially around something.

Example: Mona twisted the wrench until the bolt head broke off.

5. spiral – something moving in a curved path around a central axis.

Example: The flutes of a drill bit are a spiral cut into the sides of that drill bit.

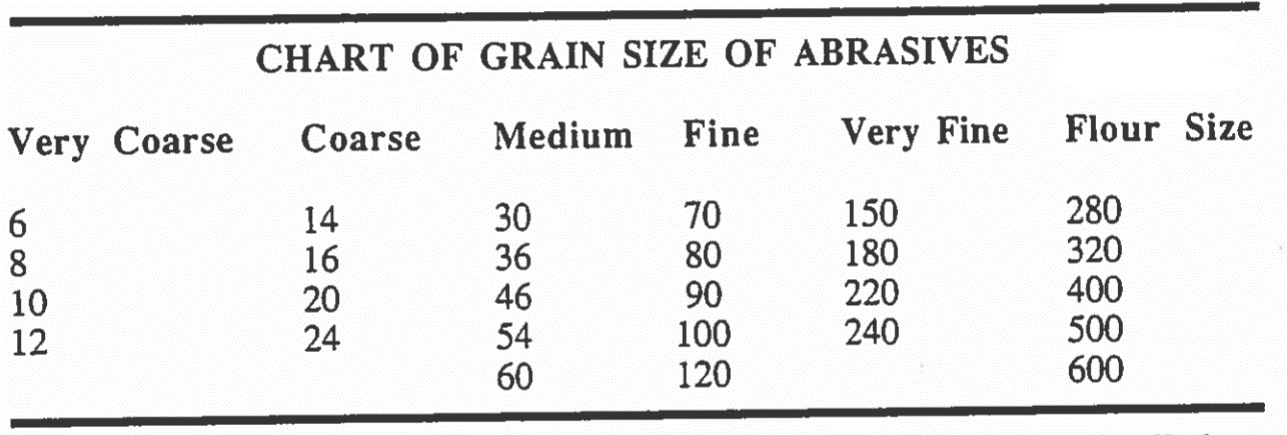

6. chart – a group of facts about something, arranged in an orderly manner, often showing quantities.

Example: Pedro looked at a chart of abrasives and decided use No. 400 for polishing.

7. grain – a very small piece of something, like sand or wheat.

Example: Gina looked as the small grains in the grinding wheel.

8. abrasive – rough material made from grains that can be used to grind into, or to polish, the surface of a workpiece.

Example: Grinding wheels are made from abrasives, especially aluminum oxide.

9. bond – any liquid material that holds many smaller things together by surrounding them and then hardening.

Example: The manufacturers of grinding wheels use various materials to make a bond that will hold grains of abrasive in place.

10. vitrified – like glass; turned into glass; once melted and now hardened like glass.

Example: When certain melted materials harden, they form a vitrified bond which is like glass.

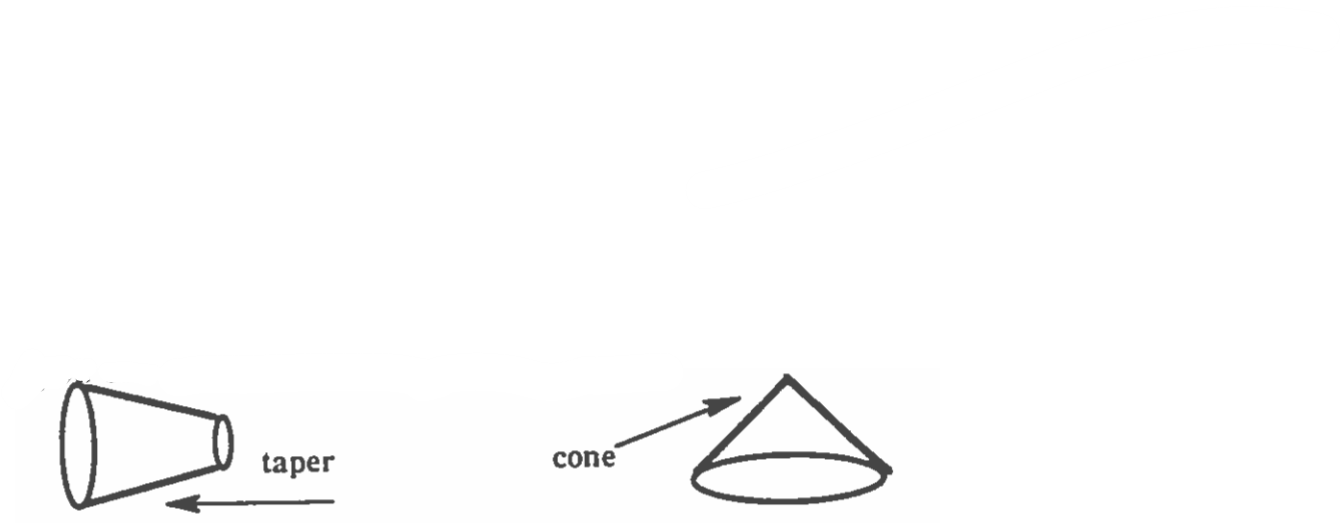

11. taper – to gradually decrease in thickness from one end to the other. Example: If a part becomes too hot while you’re machining it, you can get an unwanted to taper in the part.

12. cone – a shape that is like a because it is round with straight sides, but it tapes from one end to the other.

Example: Can you think of something that is shaped like a cone besides an ice-cream cone?

Vocabulary Practice for Set C

3. Drills:

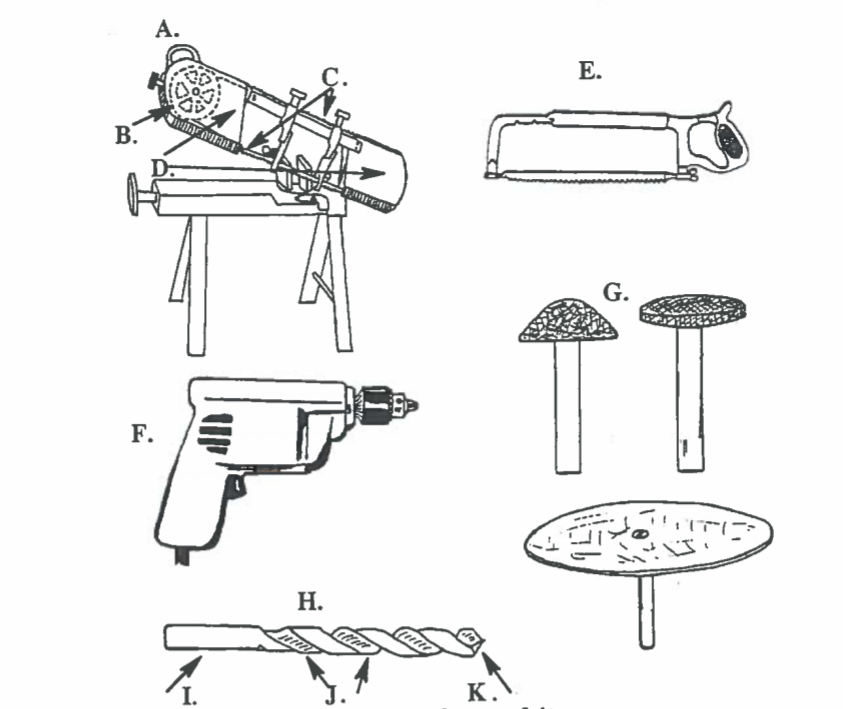

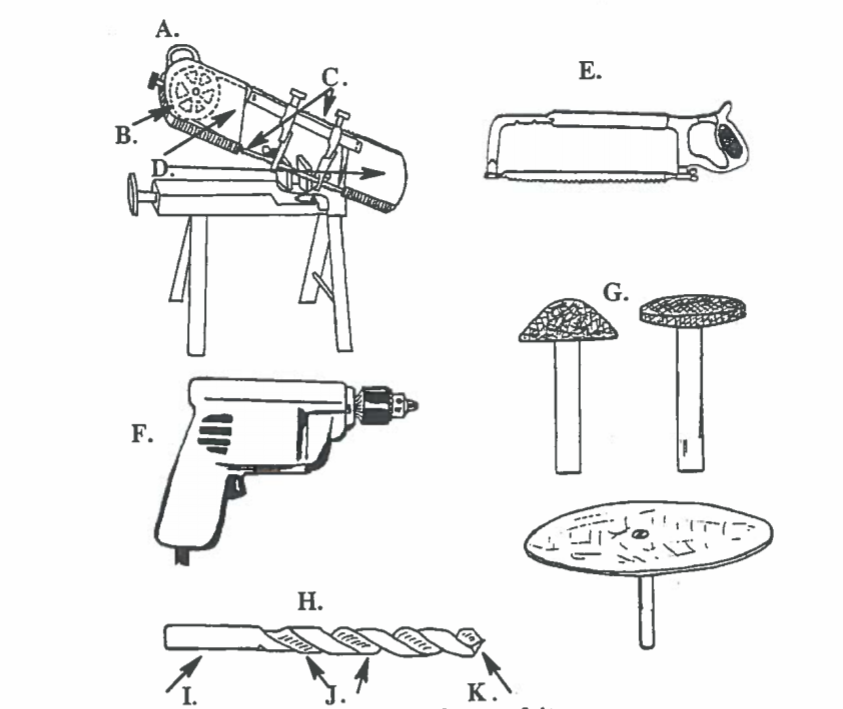

The electric drill is one of the portable power tools. It can be held in the hand and turned on by pulling a trigger with the finger, like a gun. On the front of the drill is a chuck for holding drill bits.

The chuck has jaws that open and close around the shank (the non-cutting end of the drill bit); the drill bit is the boring tool itself. The drill has a tip (at the opposite end from the shank) with cutting lips. The drill bit can also have one or more rounded grooves that spiral around the sides of the drill bit – these grooves are called flutes. A drill bit with flutes can also be called a ”twist drill,” because of its twisted, spiraling shape.The drill bits come in a variety of sizes, and with different numbers of flutes. The chuck can be opened to receive larger sizess or tightend to hold smaller sizes. The chuck is tightened or loosened with a chuck key. We will learn more about drills, drill bits, and drilling when we study the module about larger power drills, like the drill press.

The chuck has jaws that open and close around the shank (the non-cutting end of the drill bit); the drill bit is the boring tool itself. The drill has a tip (at the opposite end from the shank) with cutting lips. The drill bit can also have one or more rounded grooves that spiral around the sides of the drill bit – these grooves are called flutes. A drill bit with flutes can also be called a ”twist drill,” because of its twisted, spiraling shape.The drill bits come in a variety of sizes, and with different numbers of flutes. The chuck can be opened to receive larger sizess or tightend to hold smaller sizes. The chuck is tightened or loosened with a chuck key. We will learn more about drills, drill bits, and drilling when we study the module about larger power drills, like the drill press.

4. Portable Grinders:

A grinder uses a grinding wheel (made of a rough material called an abrasive) which spins around and (with pressure) cuts small chips out of the surface of the workpiece. There are various abrasives used to make grinding wheels: About 75% of grinding wheels are made from aluminum oxide; this material is used in the form of little, gray or white-colored grains with tough, sharp edges that cut into the work material. Other materials used for abrasives include silicon carbide and diamond. The size of the abrasive grains vary from fine to coarse. The grain size used will depend on the job and the material being ground. On a chart of grain size the most coarse grains will have small numbers and the fine grains will have large numbers.

The grains are held together in the shape of a wheel b a material called bond. A common material used for bonding the grains together is clay or feldspar; these materials, when heated to a high temperature, melt and form a glass-like layer around the grains, holding them together. This is called a vitrified bond. Other bonds use materials like resin, rubber, shellac, silicate, or metal.

The grains are held together in the shape of a wheel b a material called bond. A common material used for bonding the grains together is clay or feldspar; these materials, when heated to a high temperature, melt and form a glass-like layer around the grains, holding them together. This is called a vitrified bond. Other bonds use materials like resin, rubber, shellac, silicate, or metal.

Grinding wheels come in a variety of sizes an shapes. They can be small enough to fit into the chuck of an electric hand drill or big enough to fir into a larger grinding machine. The shapes can be round and flat, or cone-shaped with tapered sides, or many other forms. You will learn with practice what shapes work in particular jobs you have to do.

Tool Names

Tool Identification

Spelling Practice

Spelling

It’s Okay to Ask Questions

Conversation No. 1:

Supervisor: Jose, I’d like you to work on a “hot job” this afternoon.

Jose: What do you mean when you say “hot job”?

Supervisor: A “hot job” is an important job that needs to be done right away.

Jose: Do you want me to stop doing what I was working on?

Supervisor: Yes, drop everything. A “hot job” has to be done immediately; in this case, we have a customer waiting for special parts in San Francisco.

Jose: Okay, I’ll get right on it.

………………………………………………………………………………………………………………

Conversation 2:

Jose: Well, what do you want me to do?

Supervisor: Take some 6-inch aluminum round stock over the horizontal bandsaw and cut off ten two-foot pieces. Then I want you to split the pieces down the middle, the long way.

Jose: So you want me to cut off some two-foot pieces from the 6-inch aluminum round stock. I’ve got that. Then what do I do? Can you repeat what you want?

Supervisor: You need ten pieces. Then you need to split each piece in the middle.

Jose: The long way? Not across the cross section?

Supervisor: Yes, you’ve got it. I’ll be back in half an hour to check.

True or False? Saws, Drills, and Grinders

Re-read the Student Information Sheets about Saws, Drills and Grinders; then do these true or false questions. Below are 20 statements on the vocabulary and reading; circle T or F.

1. A hand hacksaw, a power hacksaw, and a horizontal bandsaw all have frames for holding the cutting blades. T F

2. Without coolant, a saw blade may bind in the workpiece. T F

3. A hacksaw cuts in two directions. T F

4. A bandsaw cuts in one direction only. T F

5. The teeth on a bandsaw point forward; on a hacksaw the teeth point backward. T F

6. The blade of a vertical saw runs parallel to the floor. T F

7. The blade on a horizontal bandsaw is held straight by two roller guides. T F

8. Cutting a large piece from some stock can be called notching. T F

9. The hand hacksaw can be used anywhere, but a power hacksaw cannot be moves from a single place. T F

10. Cutting out an irregular piece from stock is called radius cutting. T F

11. The tip of a twist drill is inserted into the drill chuck and tightened with a chuck key. T F

12. The words “spiral” and “twist” are similar in meaning. T F

13. The smaller numbers in a grain-size chart refer to the fine abrasives. T F

14. A cone is a tapered shape. T F

15. A common kind of grinding wheel uses aluminum oxide as an abrasive, held together by a vitrified bond. T F

16. A drill bit can have three flutes twisted around it. T F

17. A chuck key is used to tighten the chuck jaws around a drill shank. T F

18. Seventy-five percent of grinding wheels are made of silicon carbide. T F

19. Some grinding wheels are small enough to be used in an electric drill. T F

20. Bonding materials for grinding wheels include rubber, shellac, clay, feldspar, and resin. T F

Listening Test:

Get the tape and play the side that say Listening Test, Module 3, Lesson 9. Listen to the words on the tape. Write the letters in the spaces.

|

1. AAA |

5. AAA |

9. AAA |

|

2. AAA |

6. AAA |

10. AAA |

|

3. AAA |

7. AAA |

11. AAA |

|

4. AAA |

8. AAA |

|

Writing Test:

Look at the pictures. Write the names.

|

A. . |

G. . |

|

B. . |

H. . |

|

C. . |

I. . |

|

D. . |

J. . |

|

E. . |

K. . |

|

F. . |

|