Lesson 5 Accessories for the Lathe

WHAT IS AN ACCESSORY?

When you are looking to buy a new car, the salesperson will ask you, “What accessories do you want on your car?”

The salesperson wants to know what extra thing you want that will make the car more useful or more fun. Do you want a radio, an air conditioning system, bluetooth, and things like that?

Accessories on the lathe are extra parts that allow the lathe to do more jobs. The accessories are usually for holding different parts, for supporting parts or for riving (rotating) parts.

ACCESSORIES OF THE LATHE

| accessory |

equipment which fits onto a machine tool and allows it to do more jobs. e.g., A lathe chuck is an accessory for holding workpieces.

|

| insert |

|

| tip |

the end of something. e.g., He touched the tip of his nose with the tip of his finger. |

| live |

alive, living, actively moving. e.g., Some lathe centers hold the work without moving – they are “dead center”; “live centers”, however, rotate with the work. |

| to machine |

to work on a metal surface by the use of a machine tool such as a lathe or milling machine. e.g., Somebody had to machine the metal which used to make a lathe. |

| to drive |

to turn the workpiece on a lathe by the use of a holding device turned by a motor. E.g., Work which is mounted between centers is usually driven by a lathe dog and face plate. |

| to pinch |

to hold something tightly between two fingers or two jaws on a machine. E.g., The jaws of the lathe chuck pinch in around the workpiece. |

| to sag |

to bend in the middle from weight or pressure. E.g., If a workpiece is long, it may sag in the middle form its own weight. |

| to align |

to bring parts into a straight line. E.g., The ways on the lathe are the means for aligning the two headstocks and the carriage. |

| simultaneously |

happening at the same time. E.g., Roberto can watch television and read the newspaper simultaneously. Related Word: simultaneous |

| off center |

not being in a straight line with a center or along an axis. E.g., If the workpiece is off center, the part will not be correctly made. |

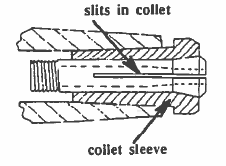

| slit |

a long, narrow opening cut into a cloth, wood, or metal. E.g., The collet had a slit on each side which make it like a spring. |

| sleeve |

|

| concentric |

having the same center. |

Ex. 8.5a

Word Find

ACCESSORIES FOR THE LATHE

As we have seen, the lathe rotates the workpiece at a rapid speed, and a cutting tool is fed into, and along, the work to shape and finish round parts. There are a variety of lathe accessories that help lathe operations by: (1) holding the work, (2) supporting the work, and (3) driving (rotating) the work.

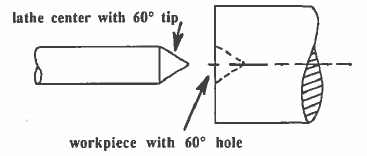

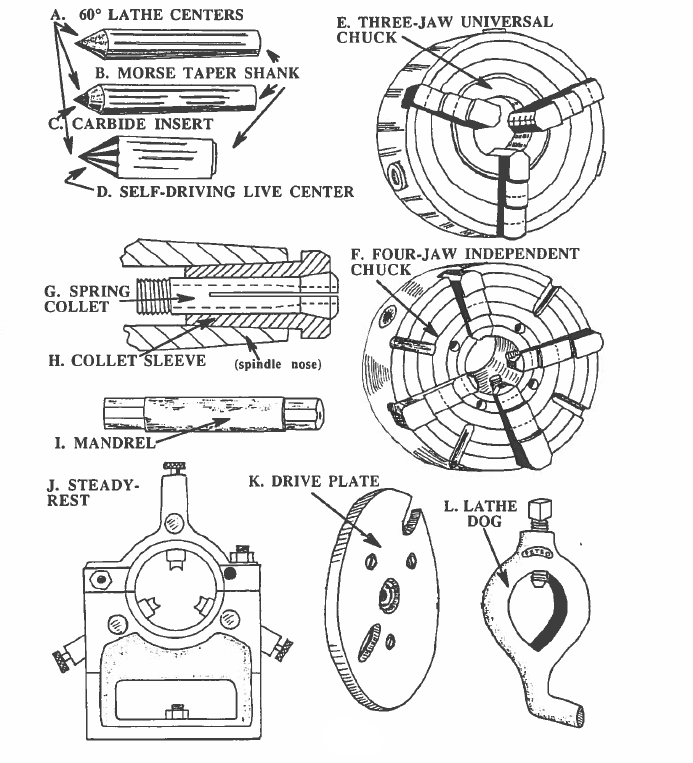

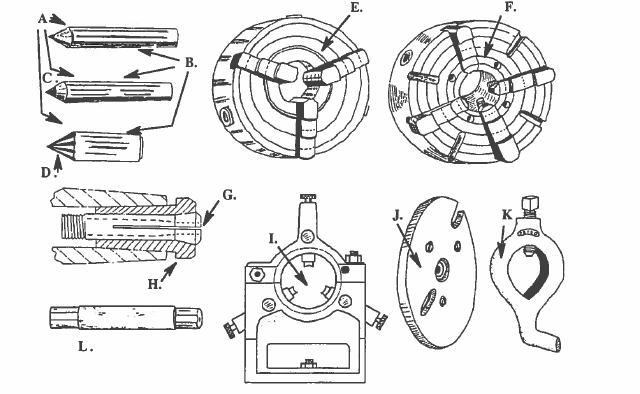

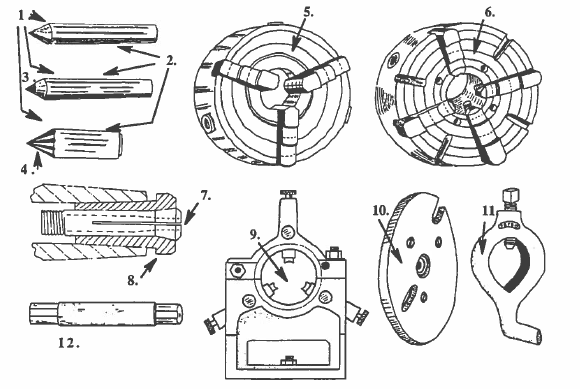

1. Lathe centers: There are many jobs that the lathe can do by mounting the workpiece between lathe centers. In the picture given on the Student Vocabulary Sheet, there are three lathe centers; each is a metal shaft with a 60o point. The shaft of the center is tapered from the thicker part, near the point, to the thinner part, near the end of the shaft; this taper is called a Morse taper. The lathe centers are inserted into the hollow spindles of the headstock and the tailstock and become very tight there, because of the taper. To remove the centers, the machinist must pound them out from the other side.

To mount a workpiece between centers, the two ends of the workpiece are drilled with 60o holes; the 60o tips of the centers fit into the 60o holes in the workpiece.

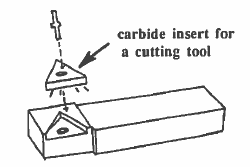

Some lathe centers have carbide inserts as tips; the carbide material will last longer than steel; an insert can be replaced when it is worn rather than replacing the whole center.

A self-driving live center has special grooves cut into the sides of the tip; the tip is driven into the end of the workpiece which is usually made of soft metal like aluminum. This kind of center will hold the work and also drive it.

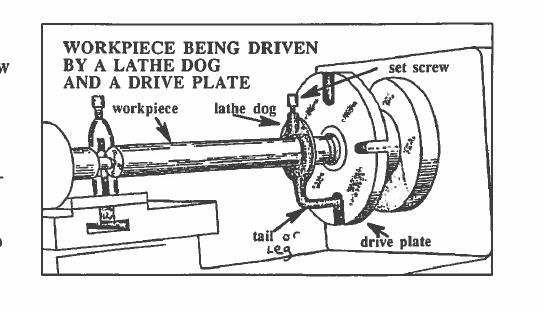

When machining between centers the usual method of driving (rotating) the workpiece is to use a lathe dog and a drive plate. (The self-driving center is used when a lathe dog cannot be used). A drive place and a face plate look very similar, but the drive plate has openings on the sides to hold the tail of the lathe dog; the holes in the face plate are used for holding work with bolts or clamps. (Cf. picture and explanation of the drive plate on the next page).

2. Lathe Dogs and Drive Plates: To drive a workpiece, when machining between centers, the workpiece can be inserted into the opening of a lathe dog; next the work is tightened inside the dog by a set screw at the top of the dog. The tail of the dog fits into a drive plate; the drive plate is rotated by the spindle. Rotation is passed from the spindle to the drive plate, to the dog, to the work.

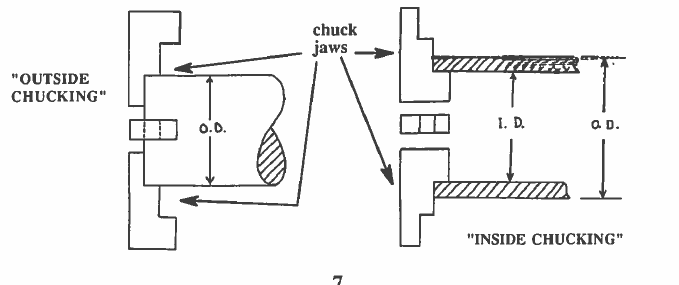

3. Chucks: A chuck is used to hold workpieces which cannot be done between centers, because of their shape or size, or when the machinist wants to have one end of the work spinning freely. The chuck has jaws, which pinch together around the workpiece when the jaws are tightened with a chuck wrench or chuck key. Chucks usually have two sets of jaws that will hold work on its outside diameter (O.D.) or will hold hollow work by its insider diameter (I.D.). Putting something into a chuck is called “chucking”; the two ways of mounting the work are called “outside chucking” and “inside chucking”.

There are two basic types of chucks:

a. Three-jaw universal chuck: This chuck has three jaws which move together simultaneously as the chuck is tightened around the workpiece. Because the jaws close at the same time, the chuck is called “universal”. This kind of chuck has a range of sizes from 4 to 16 inches.

b. Four-jaw independent chuck: This chuck has four jaws, each of which can be tightened separately (independently) by a chuck wrench. With this kind of chuck, the lathe can hold round, square, or other shaped kinds of work.

Because the four jaws operate independently, it is possible for the work to be off-center when it is first put into the chuck. To make sure the work is correctly centered, a dial indicator (Mod 5, Les 3, p. 21) can be used to see how far off center each side of the workpiece is; then adjustments to the jaws can be made. If, for example, one side of the workpiece is .010 inches off center, the machinist will move the piece .005 inches in the opposite direction in order to correctly center the work.

4. Collets: A collet is a kind of chuck, used when extremely high accuracy is needed. The collet in picture is a spring collet. It is open in the middle to receive the workpiece. It has two or more slits in the sides running from the front of the collet towards the back. It has two or more slits in the sides running from the front of the collet toward to back. When the collet is drawn back into the collet sleeve by a draw bar, the slits are narrowed as the collet pinches tightly around the work. when the pressure is released, the sides of the collet will spring back to their original size.

5. Steadyrest: This lathe accessory is used to support the middle of long pieces of work that would tend to sag if they didn’t have extra support. The steadyrest can be used to support long pieces that are being machined between centers or that are sticking out of a chuck. The steadyrest can be located anywhere along the ways and is aligned by them.

6. Mandrel: The mandrel is mounted between centers. It is useful for mounting and driving work that has an inside diameter. This will insure that further work on the O.D. of the workpiece will be concentric with the axis of the workpiece.

Ex. 7.5 Matching

Exercise 2: Load the tape recorder with the cassette tape marked Module 7, Lesson 5, Dictation. Listen to the tape as you look at the paragraphs below. Fill the word you hear into the blanks below. Then check your spelling. Then listen again to make sure you understand what is said. Then try listening to the tape without this sheet.

- Lathe centers usually have a with a 60o .

- The center is from the front to the rear of the .

- This taper is called a taper. To remove a lathe center, the machinist must it out.

- Most work done … is driven by a

- … with its tail in a …

- .

- A set holds the work in the dog.

- Chucks are another way to a workpiece. There are . kinds of lathe chucks: (1) the three-jaw chuck in which all three jaws close and (2) the independent chuck in which the jaws are closed one-at-a-time around the .

- A is kind of a chuck. The machinist uses it for high

. The work slips into the ; the

will close around the work when it is pulled inside a .

- A keeps a long, thin workpiece from . Work with an can be mounted on a for work on the

- .

Mark & Betty, two lathe operators are talking.

……………………………………………………………………………………………………..

Conversation No. 1:

|

Mark: |

Hi Betty! You on break now? |

|

|

Betty: |

Yes, I just started. Sit down and talk to me for a couple of minutes. |

|

|

Mark: |

I had a good morning! I started using those carbide inserts on my toolbit, and now I don’t have to mess with regrinding the cutting edges. It gets dull, and I just throw in a new one. |

|

|

Betty: |

Hey, that’s good. I’ve been using carbide toolbits and centers for quite a while. They last longer, and my production has gone up. |

|

……………………………………………………………………………………………………..

Conversation No. 2:

|

Betty: |

Mark, I have this long, thin workpiece I need to do. What setup should I use? |

|

|

Mark: |

I’d recommend doing it between centers, with a steadyrest in the middle to keep it from sagging. |

|

|

Betty: |

The steadyrest is a good idea! That’ll preserve my concentricity. |

|

|

Mark: |

That’ll be five dollars for my consulting fee. Just kidding! |

|

……………………………………………………………………………………………………..

Conversation No. 3:

|

Mark: |

I’ve got to make a cylindrical steel sleeve and the procedure has several steps. |

|

|

Betty: |

Tell me about it. |

|

|

Mark: |

Well, I’m going to get the I.D. first. Then I’m going to mount the work on a mandrel and work on the O.D. |

|

|

Betty: |

Sounds easy. You’re lucky it doesn’t have a taper. |

|

Ex. 7.5 Accessories for the Lathe

Ex. 7.5 Matching Names of Accessories

Ex. 7.5 Spelling

Ex. 7.5 ACCESSORIES FOR THE LATHE

a cutting edge or tip which can be replaced when it is worn. e.g., Josefina replaced the carbide insert in her cutting tool.

a cutting edge or tip which can be replaced when it is worn. e.g., Josefina replaced the carbide insert in her cutting tool. a metal part, like a tube, which fits over or around another part.

a metal part, like a tube, which fits over or around another part.