Lesson 1: Introduction to Hand Tools (Portable Bench Tools)

A worker in any trade can do a better job with good tools. The tools help the worker do the job more quickly and more easily. Without tools, some jobs are impossible.

A machinist is often cutting and drilling hard materials, like metal. Without tools, the machinist’s job would be impossible. Some of the machinist’s tools are large and are powered by electric motors; some of the tools are small and can be held in the hand. If the machinist can hold the tool with his/her hand, it is called a hand tool.

Part of your job now is to learn about the hand tools that you will use when you go to the Machine Shop Classes. It is necessary to learn the names of the common hand tools. It is also necessary to learn each tool’s purpose. what it is for. You will not learn how to use the tool in the VESL class, but you will be able to talk about it and know what it is for. Knowing these words will be a big help when you go to the Machine Shop Classes. When the teacher talks about a tool or tells you to get one, you will know what he is saying.

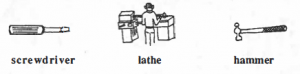

In the pictures above, only two of the tools are hand tools. the screwdriver and the hammer. The other tool is a lathe; it is a large machine, bigger than the worker; it is used for cutting rough stock to make finished parts. The lathe is powered by a large electric motor.

Often the machinist does his/her work at a work table which is called a bench. The bench can be made of metal, wood, or other strong material. Sometimes hand tools are called portable bench tools. The word portable means that you can pick up the thing and carry it. In the pictures, the screwdriver and hammer are portable; the lathe is not portable.

Vocabulary exercise

A Machinist’s Tools

1. Without good tools, a machinist’s job is impossible. With the right tools, a machinist can make almost anything: all the metal and plastic parts that go into an automobile; all the screw, bolts, and nuts that hold machines together; all the machines that we have at home and at work.

2. Without the machinist’s tools help him/her to make accurate parts, parts that are the correct size and shape so that they fit together well.3. Later, we will study the large, power-driven machines that cut and drill. For now, we want to learn about different kinds (types) of hand tools.First, there are holding tools: the work-piece must be held tightly when the machinist is working on it.

Second, there are small cutting tools, any tools that are used to remove material from the workpiece. Third, there are non-cutting tools that the machinist uses for a variety of purposes.

Reading Technique: READING FOR DETAILS