Lesson 3: Accuracy and Mathematics

Word List

| 1.) accurate | for a machinist, to be accurate means to make parts having the correct dimensions–not too large, not to small.

Example: A machinist must make accurate parts, if he/she wants to keep his/her job. Related Word: accuracy. |

| 2.) perfect dimension | a dimension is any measureable length. A “perfect dimension” is the dimension that does not vary from the correct length; it is. the correct length. Other words for perfect dimension are: exact dimension and basic dimension. Example: The engineer is the one who decides what should be the perfect dimensions for a part. |

| 3.) actual dimension | “actual” means that which really is, what exists in reality. The actual dimension is not the perfect dimension, but what ever the dimension is in reality.

Example: The engineer’s plan wanted a perfect dimension of 2.500 inches; the actual dimension was 2.503″. |

| 4.) deep | how long the dimension of something is, when measured down into a hole or somethng like a hole.

Example: This hole is 3.575 in. deep. |

| 5.) to figure out | to get the answer to a problem; to get an idea about what to do about a problem situation; to compute an answer.

Example: Ruben, the engineer, figured out the basic dimensions for the gear he wanted the machinist to make. |

| 6.) ahead of time | to do something before the time when it was scheduled to be done.

Example: We were going to meet at 6:00 p.m., but we both arrived at the restaurant ahead of time; I got there at 5:45 and Mary came at 5:50. |

| 7.) upper limit | the largest size a part can be and still fit with the other parts.

Example: The upper limit on the width of this plate is 6.075″. |

| 8.) lower limit | the smallest size a part can be and still fit with the other parts.

Example: The lower limit for the plate is 6.065″. |

| 9.) acceptable | able to be accepted; for a machinist, a part is acceptable when its dimensions are within the upper and lower limits–the dimensions are not too large and not too small.

Example: Juan, is 4.007 inches an acceptable dimension for this part? |

| 10.) variation | how much something is allowed to be different from the basic dimension and still be an acceptable dimension.

Example: The basic dimension should be 5.000 inches, but a variation of .003 in. in either direction is okay. |

| 11.) tolerance | the amount of variation allowed in the dimension of a part. Tolerance is usually given as a plus or minus number which can be added or subtracted from the basic dimension.

Example: In the expression 2.009 + .005, the 2.009 is the exact dimension; the ±. 005 is the tolerance. Related Words: plus = the plus sign (+) tells us we should add. |

| 12.) scrap | parts are scrap if their dimensions are bigger or smaller than the tolerance allows.

Example: If the lower limit for a dimension is 5.003, then a dimension of 5.001 is too small; it’s scrap. |

| 13.) test run | the process of making the first few parts, using new blueprints; then testing to see if the parts will fit correctly.

Example: Samuel will do a test run on this new part. |

| 14.) to show up | when something happens; when something appears.

Example: The supervisor did not understand why so many scrap parts were showing up. He thought that some of the machinists were not being careful enough. |

| 15.) while we’re on the subject | because we are talking about a subject, I will use this opportunity to talk about it further.

Example: While we’re on the subject of money, what happened to the $500 you owe me? |

Spelling

Vocabulary Practice

ACCURACY AND MATHEMATICS

You already know about fractional and decimal inches:

- How the inch is divided into fractional parts and into decimal parts and how to name these parts.

- How to read and write fractional and decimal parts of an inch from the scales of a ruler.

Now we want to learn that a machinist must measure things carefully: Before a part is made in the shop by a machinist, an engineer must make a drawing of the part; this picture is called a blueprint (more about blueprints in Module 6). On the blueprint, the engineer will also give the dimensions of the part: for example, how long the part is, how wide, how high, how big are the holes in the part, how far apart are the holes, how long and wide and deep is a slot cut into the part, and other information requiring careful measurements.

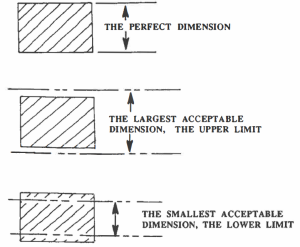

The engineer knows that the machinist will have a difficult time making the part with perfect dimensions in all places on the part. Therefore the engineer also figures out how much larger or smaller than the perfect dimension the actual dimension can be. How much larger the dimension can be is called the upper limit. How much smaller the dimension can be is called the lower limit. The upper limit is also call the maximum acceptable dimension; the lower limit is also called the minimum acceptable dimension.

So we see that, although the engineer has a perfect (exact) dimension in mind when he/she makes a blueprint, he/she will allow for variation in the actual size of a dimension, within the upper and lower limits. The amount of acceptable size variation for a finished part is called tolerance. “Tolerance” is a word you will hear often in conversation about the size of parts, when engineers and machinists talk.

If dimensions are longer than the upper limit or shorter than the lower limit, they are outside the tolerance and they are called scrap. In the ordinary use of the word “scrap” we mean 11garbage,” something to be thrown away. For a machinist, “scrap” means a dimension that falls outside the tolerance. If the dimension of the part is longer than the upper limit, it can usually be made smaller. If the dimension is shorter than the lower limit, the missing material can not be put back, and the part is scrap in the ordinary sense of the word. Supervisors at a machine shop are not very happy when a machinist who works for them makes too many scrap parts. It is a waste of time and materials.

Below are some pictures showing what you have just read about.

Here are three rules that will tell a machinist if a dimension is acceptable:

1. Every dimension between the upper and lower limit is an acceptable dimension.

2. Every dimension larger than the upper limit is scrap (not acceptable).

3. Every dimension smaller than the lower limit is scrap (not acceptable).

On the blueprint, the engineer will write the dimensions of parts in this way:

THE PERFECT DIMENSION plus or minus THE TOLERANCE

For example, 4.021 ± .00S. This tells us that the perfect dimension is 4.021 inches. (We do not need to write inches or in. or ” because it is understood we are talking about the dimension in decimal inches.) It also tells us that the tolerance is plus (by adding) or minus (by subtracting) .005 inches. When we add .005 to 4.021 we get the upper limit of 4.026; when we subtract .005 from 4.021 we get the lower limit of 4.016.

This means that any of these dimensions would be an acceptable dimension:

|

4.026 (the upper limit) 4.025 4.024 4.023 4.022 4.021 (the perfect dimension) 4.020 4.019 4.018 4.017 4.016 (the lower limit) |

|

TOLERANCE |

That also means that dimensions like the following would NOT be acceptable:

TOO LARGE: 4.123, 4.027, 4.029, 4.030, 4.200, etc. (They are SCRAP.)

TOO SMALL: 4.015, 4.011, 4.009, 4.001, 3.999, etc. (They are SCRAP.)

Tolerance Practice

Listening

(1) Listen to the conversation once;

(2) then repeat each part after you hear it;

(3) then practice the conversation with a student partner.

SITUATION: Carlos, an engineer, has completed drawing a set of blueprints. He wants Samuel, a machinist, to make the first part, using the blueprints.

C: Samuel, let’s look at these blueprints.

S: Okay! How can I help?

C: I made this blueprint recently and I want you to make the first from the blueprint.

S: I’ll be glad to do a test run for you. How much are the tolerances?

C: For most dimensions, it’s .005°, but there’s a slot with a .001″ tolerance on the width. You need to watch that one closely.

S: Okay. I’ll be careful. Maybe I can get that one exact.

C: I know you’ll do your usual good job.

S: They don’t call me “No-Scrap-Samuel” for nothing.

C: Say, while we’re on the subject of scrap, I heard that the supervisors are worried about quality control-there’s too much scrap showing up.

S: Yeah, it’s all coming from a , few workers who have only a little experience or who don’t care. Most of us have the experience to be accurate, and we care about our work.

ADDITIONAL INFORMATION

Here are some additional ideas about dimension which are important for a machinist to know:

1. Another Way to Write the Dimensions:

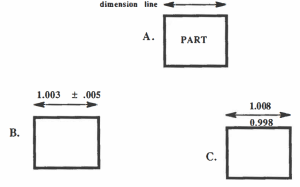

Sometimes the blueprint will not give the exact dimension plus a tolerance, but instead will write the upper limit above the dimension line, and the lower limit below the dimension line. The dimension line in the straight line with an arrowhead on each end.

In picture A, we see a dimension line, with two arrowheads.

In picture B, we see a dimension shown with a dimension line, an exact dimension, and a tolerance.

In picture C, we see a dimension shown with a dimension line, an upper limit and a lower limit.

2. Other Measurements that Require Accuracy:

Another word that is important for accuracy is the word allowance.

Allowance is the intentional difference in the size of mating parts. Intentional means “planned”; mating parts are two parts in which one of the parts fits into the other; for example, a shaft fits into a hole, or a threaded bolt fits into a threaded hole. On the blueprint, both the shaft and the hole would be shown with maximum and minimum sizes which would give the best fit.

A related word that is important for accuracy is the word fit. Fit tells us how closely the parts fit together. There are two kinds of fit:

- Clearance fit: When the shaft is put in the hole, there is enough room for the shaft to tum in the hole without sticking. Clearance is the amount of space between two parts.

- Interference fit: Here there is no space left between the parts; in fact, the shaft may be slightly larger than the hole. It will be necessary to force the shaft into the hole. With this tight fit, the two parts will act as one.

Vocabulary Practice