Lesson 5 Cylindrical Grinders

Pre-reading

CYLINDRICAL GRINDERS

Word List

| 1.) application | the act of putting something to work. e.g., One of the applications of the grinding wheel is sharpening tools. |

| 2.) cross-reference | a message to go to another part of the book for additional information. e.g., Lois noticed a cross-reference that told her to go to another page. |

| 3.) dense | having a thing’s parts placed closely and tightly together. e.g., When a grinding wheel’s grains are packed tightly together, the wheel is dense. Related Word: density. |

| 4.) to find out about | to discover, to learn about. e.g., By talking with Hazel, Kim was able to find out about how to use his textbook. |

| 5.) hinge | a joint on which a door, a lid, or any other device swings. e.g., The internal grinding head can be swung down for use, because it’s on hinges. |

| 6.) index | an alphabetical list of important topics (and page numbers) at the back of a textbook. e.g., Roman, use the index to find the page for abrasive grain size. |

| 7.) to look up | to search for something in an index, a dictionary, or any other alphabetical listing. e.g, I looked up “grinding” in the index; then I looked up Joe’s number in the phone book. |

| 8.) major | most important, main. e.g., The major reason older people come to California is to enjoy the good weather. |

| 9.) open | having a thing’s parts placed loosely together, the opposite of dense. e.g. The grains in this grinding wheel are farther apart–it’s an open wheel. |

| 10.) orderly | arranged in some regular order, neat. e.g., The Marines marched into Mogadishu in orderly columns. |

| 11.) reference | a place in a textbook where a certain topic is talked about. e.g., Find all the references in the textbook that talk about different kinds of abrasives. |

| 12.) saucer | a small, flat dish that holds a cup. e.g., Coffee cups and tea cups are usually sold with saucers to go under them. |

| 13.) to trip | to hit a switch in order to start, stop, or change how a machine runs. e.g., Joel tripped the lever, and the table changed the direction in which it moved. |

| 14.) void | empty spaces between things. e.g., A grinding wheel contains grains, bonding material, and empty spaces called voids. |

Spelling

Fill in the Blanks

Matching Definitions

CYLINDRICAL GRINDERS

1.) The Purpose of the Cylindrical Grinder: As the name indicates, a cylindrical grinder is for grinding round work, either cylindrical or tapered; with a cylindrical grinder, a machinist can grind a very accurate diameter and put any of a variety of finishes on the surface of the work. Often work which has been shaped on a lathe can be transferred directly to the cylindrical grinder for finishing, even using the same center holes that held the work between centers on the lathe.

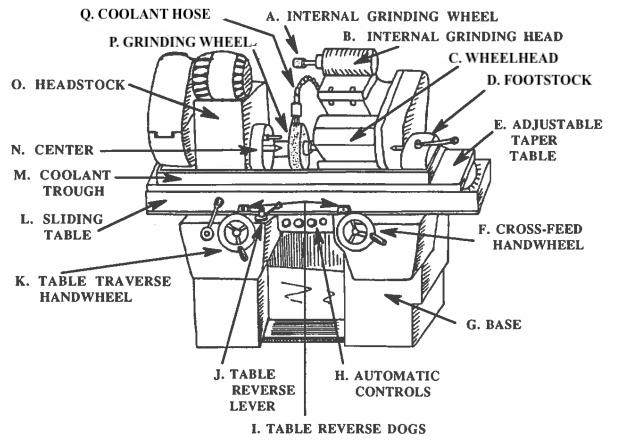

2.) The Main Parts of the Cylindrical Grinder: As you read this section, look at the pictures of the cylindrical grinder shown on page 11.

A.) Base: As with the surface grinder, the cylindrical grinder rests on a heavy cast iron base. Inside the base are housed the hydraulic power system and, on some models, the coolant system (on other models, the coolant system may be a separate unit in its own housing.) Into the top of the base are cut longitudinal ways upon which the sliding table (longitudinal traverse table) travels.

B.) Sliding table and adjustable taper table:

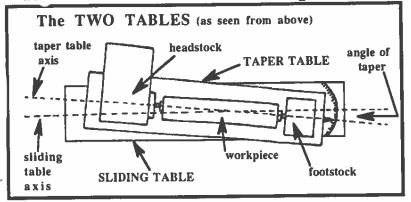

The cylindrical grinder has a two-level table: The bottom level is the sliding table; it moves back and forth on the longitudinal ways; its direction is reversed at the end of each stroke when a table reverse lever is tripped by one or the other of the two table reverse dogs, just as it happens on the surface grinder. The upper level is the adjustable taper table; it is mounted on top of the sliding table and moves with the reciprocating motion of the sliding table. However the taper table can be swiveled from its alignment with the sliding table, whenever the machinist wants to grind a taper on a round workpiece; then the axis of the taper table will be set at some angle to the axis of the sliding table (see picture above).

The motion of the sliding table can also be controlled by the table traverse handwheel, if the machinist wants to stop the reciprocating motion and manually control the motions of the table.

C.) Headstock and footstock: Before you read the following, you may want to review Mod 7, Les 2, p. 10, about the headstock and the tailstock on the lathe.

Mounted on the taper table are both a headstock (at the left) and a footstock (at the right). They move with the same reciprocating motion as the two tables to which they are mounted. The headstock spindle is powered by a motor and belts. The headstock and the footstock can be fitted with dead centers to hold (but not drive) round work; when this set-up is used, a drive plate and a driving dog are used to rotate the workpiece. The dead center of the footstock is spring-loaded to keep steady pressure on the work and provide a secure hold. The footstock can be moved along the table to accommodate work of various lengths.

The headstock can also be fitted with a three-jaw or four-jaw chuck for holding short-length work. Also, work can be directly fastened to a face plate. As you can see, these set-ups are similar to those used on a lathe.

D.) Wheelhead:

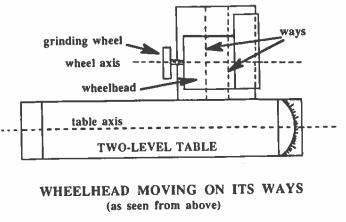

The grinding wheel is held in the spindle of a wheelhead. The axis of the grinding wheel is parallel with the longitudinal axis of the sliding table; (earlier, we saw that the axis of the surface grinder wheel is perpendicular to the axis of the sliding table; cf. Mod 9, Les 4, pp. 6-8).

The grinding wheel is not moved down into the work; rather the whole wheelhead is mounted on a set of ways which are cut at right angles to the ways of the sliding table. This allows the wheelhead (and the grinding wheel) to be fed in and out toward, or away from the spinning work. This allows the necessary depth of cut to be made.

The motions of the wheelhead in or out, toward or away from the work, are controlled by the cross-feed handwheel or by the automatic controls.

E.) Internal grinding: In the main picture, you can also see the internal grinding wheel; it is rotated by the motor in the internal grinding head. In the picture, the internal grinding head and wheel are swung up out of the way of the axis between the two centers; that leaves the area clear for the advance of the regular grinding wheel into the work. But when the machinist wants to use the internal grinding wheel, it can be swung down on its hinges (shown below the picture of the internal grinding head) into the path of the headstock. Work, which is to have internal grinding, will then be mounted in a chuck attached to the headstock; the footstock will be moved to the right out of the way. Then the internal grinding wheel is inserted into a previously machined hole in the work, in order to grind the exact interior diameter and the desired finish.

LET’S SEE WHAT YOU LEARNED:

Comprehension Check

Tell whether the surface grinder, or the cylindrical grinder, or both, have the named feature.

CYLINDRICAL GRINDERS

Vocabulary Practice

Exercise 9.62

CYLINDRICAL GRINDERS

ADDITIONAL READING IN THE TEXTBOOK

Reading Skill: USING THE INDEX

The table of contents are one place to look if you wish to find where a certain topic is located in a textbook. However sometimes the reference in the Contents is too general; e.g., imagine that you want to know something about the bonds in grinding wheels: You look in the Contents and see that Section 15 is about “Grinding”, but you do not see the word “bond” anywhere in the unit titles.

Where would you go to find the location of information on “bonds”? You could turn to page 569–the beginning of the section on grinding–and just start looking through the pages one after another. OR you could use the INDEX.

The INDEX is at the back of the textbook, on pages 907 to 925. It is a list of key words and phrases listed in alphabetical order. It is usually quite easy to find a topic or idea in the index.

Open the textbook to the INDEX.

Look now for the word “Bond,” under the B’s.

Oops! The word is not there! Now what? In the indexes of many text books all the key words are listed alphabetically in one list. Your textbook has one added step. The authors have listed only the major ideas in alphabetical order; then under each main idea they list the smaller topics, again in alphabetical order (under the main idea). If you do not find “bond” under B, you need to think of a larger idea under which “bond” might come.

You should think this way: “I don’t find ‘bond’ under the B’s, so what main idea will ‘bond’ be under? The bond I’m thinking of is the material that holds the abrasive grains together in making a grinding wheel–some main ideas that I can try are ‘grinding,’ ‘grinders,’ and ‘grinding wheels.’ Let’s see if any of those are given in the INDEX.”

Now open the textbook to the INDEX, and see if you can find the word “bond” listed under any of the main ideas about “grinding.”

Conversation Practice

SITUATION: Kim and Hazel, two students in the Machine Shop VESL class are talking during lunch time.

Kim: Hazel, I’ve got a couple of questions for you. Can you help me.

Hazel: Well, I’ll try. What is it?

Kim: I want to find out more about grinding wheels. I hear people using words like grade, and structure, and bond–and I don’t know what they mean.

Hazel: Kim, have you looked in the textbook? It’s got a lot of information on grinding wheels and other stuff about grinding.

Kim: I tried looking at it, but I couldn’t find what I wanted.

Hazel: Did you use the index or the table of contents?

Kim: Table of contents? Index? What are they?

Hazel: You must have missed class when we talked about looking up things in a textbook. The table of contents is in the front–it’s like a map that outlines what the book contains, section by section.

Kim: And what about the index?

Hazel: It’s the best source for looking up a certain idea. It lists key topics in alphabetical order. It’s located in the very back of the book.

Kim: Is that where I’ll find information about grinding wheels?

Hazel: You won’t find the information there, but you’ll find your key topic listed along with references to different pages in the textbook.

Kim: Oh, I see. I look up the idea in the index, and the index will give me the numbers of the pages that talk about my topic.

Hazel: Exactly! Go to it man!