Lesson 4 Arbor-Mounted Milling Cutters

Warm Up

Note: In previous lessons you have studied different kinds of milling machines. In this lesson you will study the different kinds of milling cutters; the cutters are very important, because they are the parts that finally cut and shape the parts that the company makes and sells.

All the others parts of a milling machine are for the sake of the cutters: the table lifts the workpiece into the cutter; the knee lifts the table; the spindle rotates the arbor or shank that turns the cutter, etc.

Keep up your good work in this lesson!

MILLING CUTTERS

(Arbor-Mounted)

Word List

| 1.) bushing | a sleeve of metal that fits around a cylinder of metal to support it. e.g., Bushings must have a source of oil to keep metal from rubbing on metal. |

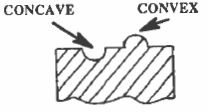

| 2.) concave | hollow and curved like the inside half of a hollow ball. e.g., There was a concave dent in the wall where the rock had hit. |

| 3.) convex | curving outward like the surface of a sphere. e.g., A concave formed cutter will leave a convex ridge in the metal. |

| 4.) hazard | Something which is dangerous or which can cause an accident. e.g., A wet road can be a hazard at night. |

| 5.) helical | In the shape of a helix. e.g. The shape of some cutting edges on a cutter are helical. |

| 6.) profile | The shape of something as seen from the side. e.g., The soldier had a very straight profile as he stood before the general. |

| 7.) rate | The speed at which something runs or moves. e.g., A cutter can be run at a faster than can a thin slitting saw. |

| 8.) to shatter | To break apart into many pieces. e.g., Paul shattered the window glass when he hit it with his head. |

| 9.) spacer | A metal cylinder used to separate one thing from another. e.g., The spacers were mounted on the arbor to hold the cutter in the right place. |

| 10.) staggered | First being on the right, then being on the left. e.g., The teeth on some side mills are staggered. |

| 11.) stuff | Things in general; the things you need for a job. e.g., “To know your stuff” means to know what you need to do your job. |

| 12.) style | a particular kind of thing with certain features different from other kinds. e.g. This style of cutter has staggered teeth. |

| 13.) to thread | to put something onto a shaft, like putting thread into the eye of a needle. e.g., Beatriz threaded the arbor through the spacers. |

| 14.) tough | Strong, difficult to hurt or damage. e.g., The high speed steel used to make cutters must be very tough. |

| 15.) to vary | to be different from others. e.g., The angle of the sun varies during the day. |

Vocabulary Practice

MILLING CUTTERS

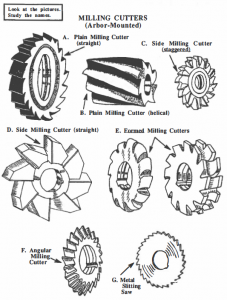

There are two main kinds of milling cutters: (1) arbor-mounted cutters and (2) shank-type cutters:

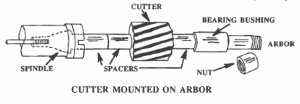

1. Arbor-Mounted Cutters: This type of cutter is shaped like a wheel with a round hole in the center. It is threaded onto an arbor and is held in place by spacers and bearing bushings and by a nut which is tightened at the end of the arbor; the other end of the arbor is then inserted into, and driven by, the spindle.

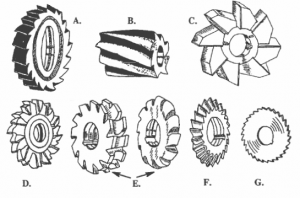

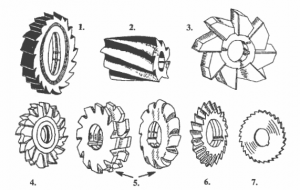

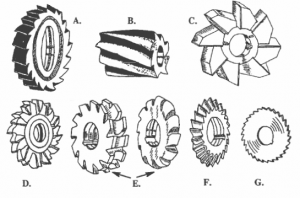

There are a wide variety of arbor-mounted cutters. They are used with the horizontal mill. Let’s look at some different kinds of arbor-mounted cutters:

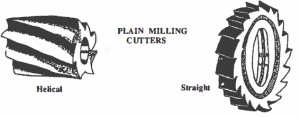

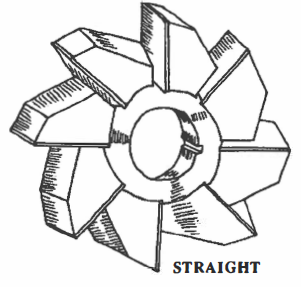

a. Plain milling cutters: A plain milling cutter is a cylinder of tough steel with cutting teeth on the periphery. They can be of two styles:

(1) straight, with teeth cut parallel to the horizontal axis of the arbor; or

(2) helical, in which the teeth curve from one side of the cutter to the other, in the shape of a helix.

Plain milling cutters are chiefly used to make flat surfaces; they do this by cutting chips of metal from the surface of the workpiece. Plain milling cutters come in a variety of sizes; on the ones that have helical teeth, the helix can vary in number of degrees, up to as much as 60° or even more. The helix-type cutter produces a smoother surface.

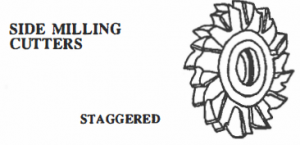

b. Side milling cutters: A side milling cutter is a wheel-shaped piece of steel with cutting teeth on its periphery and on its side or sides. Such cutters are usually narrower than the plain milling cutter. The teeth on this cutter can be straight or staggered; the staggered type has teeth which are set in alternate positions on the right and the left side of the cutter.

Side milling cutters are good for cutting slots, especially deep, narrow ones.

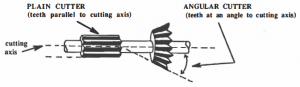

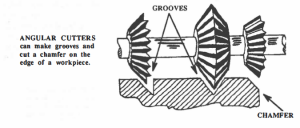

c. Angular milling cutters: An angular milling cutter has teeth that are at an angle to the cutting axis (the horizontal axis of the arbor); they are neither parallel nor perpendicular to that axis, but are at some other angle.

Angular cutters come in a variety of sizes and angles; some have teeth only on one side of the cutter; others have teeth on both sides. Some of the uses of an angular

cutter are: to cut grooves, to chamfer edges, and to cut teeth into reamers (Mod 3, Les 6).

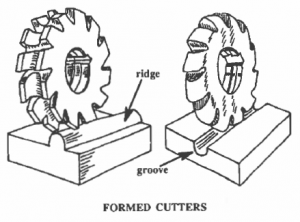

d. Formed cutters: A formed cutter has cutting teeth on its periphery which are used to cut special shapes, e.g.,

(I) a concave-shaped cutter will cut a convex shaped ridge,

(2) a convex cutter will cut a U-shaped groove, and

(3) a third shape can be used to cut gear teeth.

The formed cutters are useful for making many exact copies of small, irregular-shaped parts.

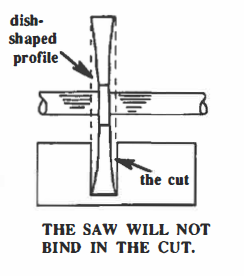

e. Metal slitting saws: A metal slitting saw is a circular saw which is fitted onto an arbor and used to cut off pieces of metal, as, for example, when a workpiece is cut off from the rest of the stock.

e. Metal slitting saws: A metal slitting saw is a circular saw which is fitted onto an arbor and used to cut off pieces of metal, as, for example, when a workpiece is cut off from the rest of the stock.

The blades vary in thickness from 1/32 to 3’/16 in.

Slitting saws have a dish-shaped profile to prevent them from binding in the cut. There is a safety hazard in the use of the saw because of the possibility of the blade shattering under heavy use. To use the slitting saw safely, machinists should run the saw at a much slower rate than for other cutters; also they should not tighten the arbor nut as much nor should they lock the blade onto the arbor.

Slitting saws have a dish-shaped profile to prevent them from binding in the cut. There is a safety hazard in the use of the saw because of the possibility of the blade shattering under heavy use. To use the slitting saw safely, machinists should run the saw at a much slower rate than for other cutters; also they should not tighten the arbor nut as much nor should they lock the blade onto the arbor.

Comprehension Check

Spelling Cutter Names

Matching

Spelling with Missing Letters

Cutter Identification

Practice Conversation

Situation: Irma, a machine shop teacher, is talking to Lee, a new student.

Conversation No. 1:

Irma: Lee, I’d like you to work on this horizontal mill today.

Lee: Okay, Inna. Where do we start?

Irma: . The first thing is to mount the cutter on this arbor. Use that helical plain cutter. And be careful you don’t cut yourself…so use this shop rag to pick up the cutter.

Lee: Yes, the blades do look very sharp. I’ll use the rag.

Conversation No. 2: Irma and Lee continue their conversation.

Irma: Okay. Run the arbor shaft through the hole in the arbor.

Lee: Yes. What’s next?

Irma: Now put these spacers and this bearing bushing on the arbor too: They’re going to hold the cutter in place on the arbor.

Lee: What’s the bearing for?

Irma: That’s the part that goes into the arbor support. It gets a lot of pressure and needs to be lubricated.

Conversation No. 3: The two continue their conversation.

Irma: Lee, can you name these other cutters sitting on the bench?

Lee: Sure. I learned those in VESL class. That’s an angular cutter. ‘Those two are formed cutters. That’s a straight side cutter and there’s another one with staggered teeth. It also looks like you have two or three different slitting saws.

Irma: You know your stuff, Lee.

Lee: Thanks!