Lesson 1 Introduction to Milling Machines

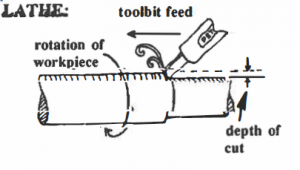

We have just finished studying the lathe, a large machine tool which spins round work and cuts that work with a toolbit. Now we will study a second machine tool, the milling machine.

The only thing better than reading about milling machines will be to use one to make some beautiful and usable parts ! !

INTRODUCTION TO THE MILLING MACHINE

Vocabulary List

| 1.) arbor | a strong steel shaft on which milling cutters are mounted. e. g., An arbor must be very strong to support the pressure of cutting. |

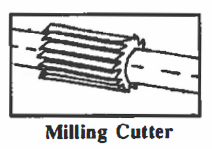

| 2.) cutter | a circular cutting tool, with teeth or blades; it is mounted on an arbor. e.g., Milling cutters are very sharp and should be handled carefully.  |

| 3.) determined by | caused to happen in a certain way because of something. e.g., The depth of cut is determined by how deeply the cutting tool goes into the work. |

| 4.) identical | exactly the same in size, appearance, quality and every other feature. e.g., Some manufacturing companies make thousands of identical parts. |

| 5.) milling machine | large machine which cuts and shapes metal by the use of rotating circular cutters with sharp cutting blades or teeth. e.g., The Cincinnati Co. makes milling machines. |

| 6.) multiple | more than one in number or times happening. e.g. , Most parts require multiple operations to finish. |

| 7.) periphery | the outside edge of a round object; same as circumference. e.g., The cutting blades are located on the periphery of the cutter. |

| 8.) to travel | for a tool or a part to move in a certain direction. e.g., The toolbit of the lathe travels along the length of the workpiece. |

| 9.) recent | happening in the not too distant past. e.g., I bad a recent bad experience: last week I went to the dentist. Related word: recently. |

| 10.) widely used | used often and in many different e.g., The auto is now much more widely used for travel than is the horse. |

Vocabulary Practice

INTRODUCTION TO THE MILLING MACHINE

The second large machine tool that we will study is the milling machine.

1. The purpose of the milling machine: The purpose of the milling machine, like the lathe, is to shape and cut material by the use of a cutting tool; the cutting tools on a milling machine are called cutters.

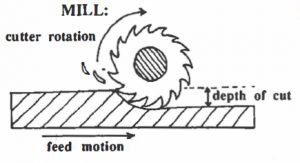

2. How the milling machine works: For milling, the workpiece is fastened to a movable table. A milling cutter is circular in shape and has teeth on its circumference (sometimes called the periphery of the cutter). The cutter is rotated at a certain speed. The workpiece is fed into the teeth of the spinning cutter, as the table is raised.

3. Types of milling machines: Like the lathe, there are several kinds of milling machines: some are made specially for manufacturing and will produce a large number of identical parts. A recent, widely-used milling machine is the machining center; it is controlled by a computer, has several cutters, and can do multiple machining operations to a workpiece.

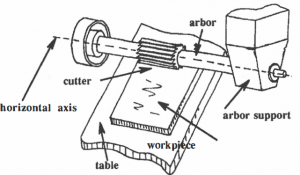

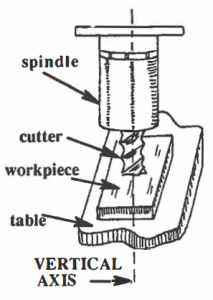

There are two common types of milling machines which you will use in the machine shop while you are training to be a machinist: the horizontal milling machine and the vertical milling machine:

a. Horizontal milling machine: In this type, the cutter is mounted onto a rotating shaft called an arbor. The axis of the arbor and the cutter is horizon-– tal (parallel to the horizontal plane of the table}.

b. Vertical milling machine: In this type, the cutter has a shank. This shank is mounted into a spindle. The axis of the spindle, the shank, and the cutter is vertical (perpendicular to the horizontal plane of the table).

4. Holding the workpiece: It is important for accuracy and safety that the workpiece be held very securely on the table. There are a variety of vises, clamps, bolts and special devices for holding work. We will study them when we look at milling machine accessories in a later lesson.

5. Comparing the milling machine and the lathe: Let us compare the cutting action of the milling machine with that of the lathe:

| Milling Machine | Lathe | |

| Tool Motion | 1.) The cutter rotates but does not travel | 1.) The toolbit does not rotate, but travels along the work. |

| Workpiece Motion | 2.) The table feeds the work into the cutter. | 2.) The workpiece rotates. |

| Depth of Cut | 3.) The depth of cut is determined by the height of the table | 3.) The depth of cut is determined by the position of the toolbit. |

Comprehension Check

Practice Conversation

Situation: Ralph, a machine shop teacher’s assistant, is showing Jennie, a new student, some of the shop machines.

Conversation No. 1:

Ralph: Jennie, take a look at these milling machines over here. This one is a horizontal mill.

Jennie: Why do they call it a “horizontal mill,” Ralph?

Ralph: Well, do you see that cylinder with the sharp blades mounted on that shaft–well, that’s the milling cutter–and it’s axis is parallel to the horizontal plane of this table.

Jennie: What’s the table for?

Ralph: That table is to hold the workpiece very steady, so it can be worked on. The cutter rotates, but it doesn’t come down on the work. Instead, the table is raised, and the work is pushed into the cutter.

Jennie: That’s different from the lathe, isn’t it? The lathe toolbit gets pushed into the rotating work–and here with the mill, the work gets pushed into the rotating cutter. Hey, I’m learning a lot!

Conversation No. 2:

Jennie: Are all mills like this horizontal mill?

Ralph: No, they’re not, Jennie. Here’s a different kind over here. It’s called a vertical mill.

Jennie: Let me see if I can guess why it’s called a vertical mill. I think it’s because the cutting blade runs up and down instead of horizontally.

Ralph: That’s right! You see the cutter has a shank on it, and the shank fits up into that spindle. When it’s set up, it looks like a drill. The axis of the cutter is vertical.

Conversation No. 3:

Jennie: You’re right, Ralph; this vertical mill looks like a big drill. Are there any differences between a vertical mill and a drill.

Ralph: Yes, there are. The biggest difference with a vertical mill is that the work is fed into the cutter by raising the work on a table–with a drill, the drill is pushed down into the work.

Jennie: But with both tools, it’s a rotating tool that does the cutting.

Ralph: Yes, that’s right. Now Jennie, can you tell me the names of the cutting tools used for a lathe, a mill, and a drill?

Jennie: Yes, I know that. The lathe uses a toolbit, the mill uses a cutter, and the drill uses a drillbit.

Ralph: You’ve got it, Jennie. You’re going to be a very good student.