Lesson 3 Parts of the Carriage

Warm-up

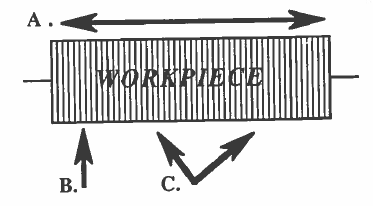

ANGLES FOR CUTTING THE WORKPIECE

The picture above represents the spinning workpiece. The three arrows represent the cutting tool which can cut the work from any of three directions:

A. represents the cutting took moving along the length of the work.

B. represents the cutting tool moving at a 90o angle into the workpiece, across the ways.

C. represents the cutting tool moving into the workpiece at any other angle except 90o.

Question:

How is it possible to cut the workpiece from these different angles? We’ll find out in this lesson. We’ll discover that parts of the CARRIAGE make this possible: (1) THE SADDLE, (2) THE CROSS SLIDE, and (3) THE COMPOUND REST.

THE CARRIAGE

It is important to give special attention to studying the carriage and the cutting tools because the machinist must learn to control these parts where the cutting actually takes place. The carriage will be studied in this lesson and the cutting tools in the next.

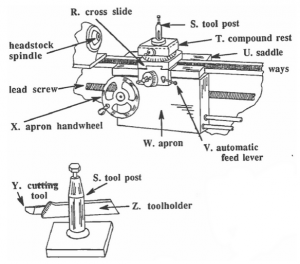

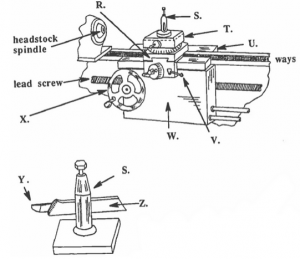

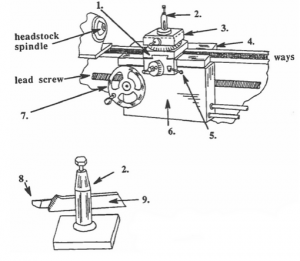

The main purpose of the carriage is to move the cutting tool to the positions where it is needed to cut the workpiece. The carriage has four important parts:

(1) cross-slide,

(2) saddle,

(3) compound rest, and

(4) apron.

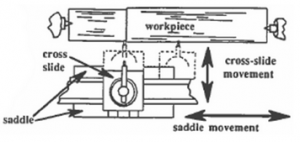

The cross slide allows the cutting tool to feed across the bed into the workpiece. The cross slide is mounted on top of the saddle; the saddle sits on top of the ways and is free to move up and down the bed of the lathe.

To summarize what we have at this point: (1) the cross-slide movement is into the workpiece, and (2) the saddle movement is along the workpiece.

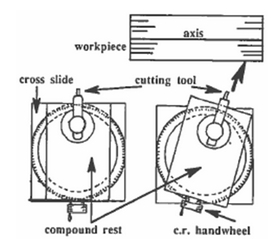

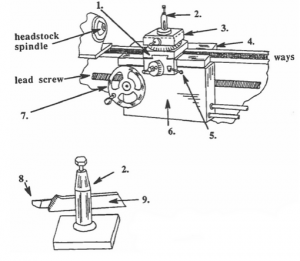

There is also a third factor in the cutting: the adjustment of the angle of the cutting tool; this angle can be changed because the cutting tool is mounted op top of the compound rest which turns in a circle to change the cutting angle. The cutting tool is held by a toolholder which fits through a slot in the tool post which sits on top of the compound rest; the compound rest, in turn, is supported by the cross slide. A collar (also called a degree ring), around the compound rest, is marked off with degrees, so the machinist can make an accurate setting. The compound rest also had its own little hand-wheel; this allows the machinist to feed the cutting tool into the workpiece by hand, to make cuts at an angle to the axis of the workpiece.

THE CARRIAGE

| to summarize |

to present ideas in a brief form. E.g., The president summarized his ideas at the end of his speech. |

| factor |

a condition that helps bring about a result. E.g., The most important factor leading to defeat was the lack of air power. |

| collar |

a ring of metal which goes around another part. E.g., The part on which the cutting tool rests has a collar with degrees on it. |

| lathe apron |

a metal shield at the middle of the lathe which protects the lead screw and other parts from chips and other dirt. E.g., The apron protects the parts from chips, chemicals, and other harmful materials. |

| automatic |

operating or regulating a machine by its own power and direction. E.g., The coffee making machine comes on automatically each morning at 6:00 am. |

Vocabulary Pratice

To summarize again: (1) the cross-slide movement allows tool feed at a 90o angle to the axis; (2) the saddle movement allows tool feed parallel to the axis; and (3) the compound rest (by turning a handwheel) allows tool feed at other angles to the axis. The feed along the axis is usually from the tailstock toward the headstock, because the headstock can better support the pressure made by the cutting tool pressing on the work.

The apron is also attached to the saddle; under the apron are the gears and parts needed to move the carriage and the cross slide automatically when the automatic feed lever is engaged. The machinist can also move the whole carriage along the lathe ways by hand, when they turn the apron handwheel. The apron protects the gears and parts from chips and dirt.

PARTS OF THE CARRIAGE

Re-read the information in this lesson. Then do the exercises.

Conversation Practice:

Situation: Isidro and Alejandro continue their conversation.

|

Isidro: |

Tell me some other things about using the lathe safely. |

|

Alejandro: |

Do you see these two new guys over there? That’s the kind of horseplay that’s going to cause an accident. |

|

Isidro: |

What’s horseplay? I don’t understand that word. |

|

Alejandro: |

Well, they’re laughing, yelling, and pushing each other – they’re playing, when they should be working. |

|

Isidro: |

What’s wrong with that? They’re just having a little fun. |

|

Alejandro: |

Horseplay can cause accidents – I’ve seen it happen. One of those guys could get pushed into the machine. You see it’s still running. Neither one of them is paying attention to their work. Production is going to go down too. |