Lesson 7: Hammers, Chisels, and Punches

WORD LIST

|

1. mar |

to make look bad with scratches, dents, or holes. Example: The part was marred, because John dropped it. |

|

2. durable |

lasting a long time even with hard or frequent use. Example: Steel is more durable metal than lead. |

|

3. stud |

a threaded metal cylinder, with no head. Example: Faustino fastened the plate over the stud by screwing on a nut. |

|

4. hold…in place |

to keep something in the place you put it. Example: A nut and a bolt will hold a part in place, if they are tight. |

|

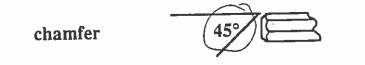

5. chamfer |

to cut the edge off a 45o angle. Example: Many times the machinist must chamfer the edges of his/her work.

|

|

6. sharpen |

to make sharp, to make a blade edge thinner, to make a point more pointed. Example: Punches must be sharpened from time to time. |

|

7. dent |

a small depression (lower place) made in a surface by hitting or by pressing. Example: The old Chevrolet had at least a hundred dents in its body. |

|

8. layout |

the drawing of lines on the workpiece to show the machinist where to cut and drill. Example: Juan looked at the layout before he made his first cuts in the metal. |

|

9. prick |

a very small puncture or hole made by a sharp point. Ex-ample: To complete the layout, the machinist puts pricks along the lines using a prick punch. |

|

10. peen |

the sharpened or rounded part of the hammer-head, opposite the face. Example: The peen on a ball-peen hammer is rounded. |

Crossword PUzzle

HAMMERS, CHISELS, & PUNCHES

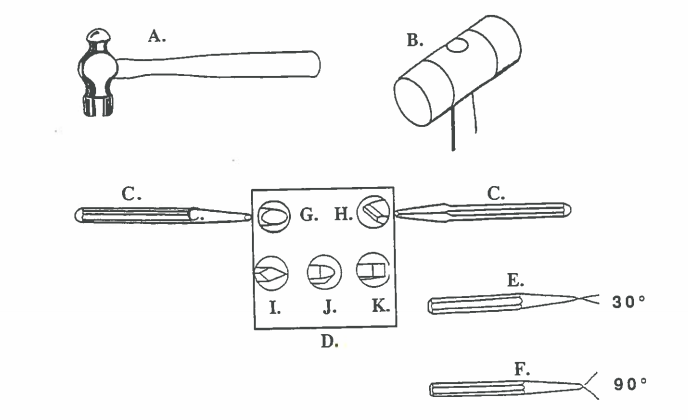

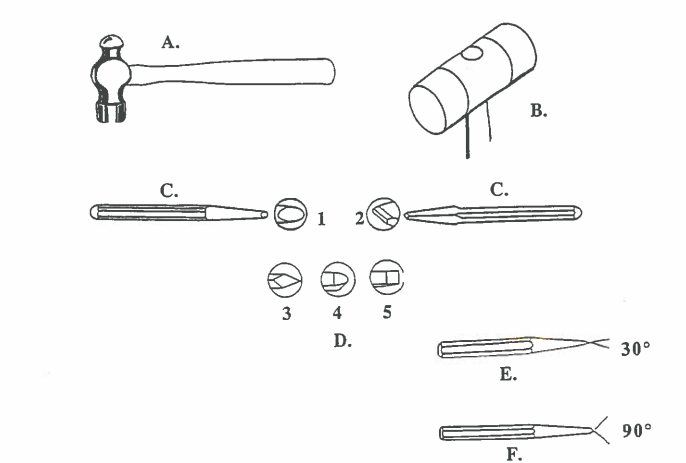

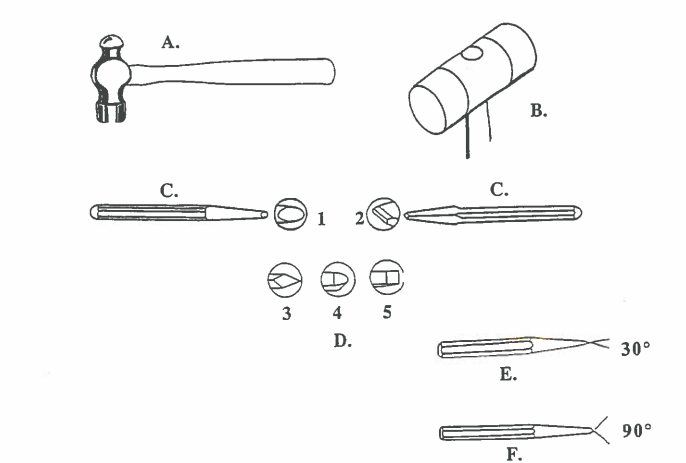

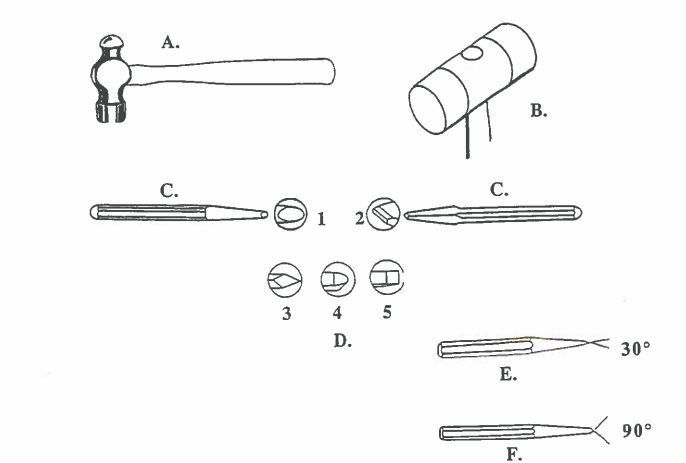

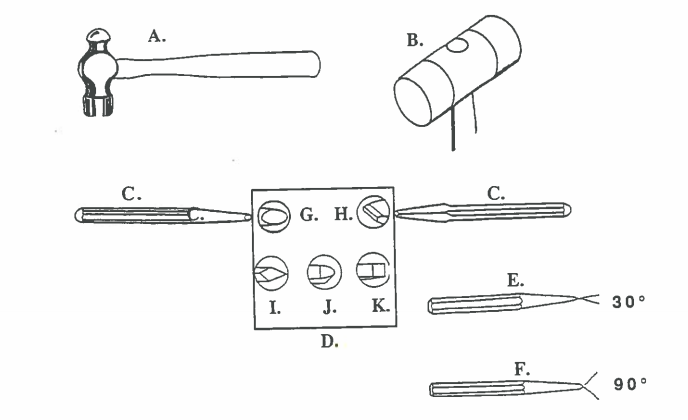

HAMMERS: One variety of hammer, commonly used by machinists, is the ball-peen hammer. It has a flat face at one end of the hammer’s head and a rounded part (called the peen) at the other end of the head. Ball-peen hammers can vary in weight from two ounces to 3 pounds.

A second kind of hammer is the plastic hammer; it is a “soft-face” hammer, a family of hammers used to pound things without scratching or marring the workpiece. Other soft-face hammers are made from material such as rawhide, copper, lead, and other “soft” materials. Plastic is more durable than some of the other materials and will last a long time.

CHISELS: Chisels are used mainly to cut off rusted or damaged bolts, nuts, and studs. (A stud is a threaded cylinder of metal like a bolt, but it does not have a head like a bolt does; it is screwed or welded into a larger piece of metal; other parts can be attached to it using a nut to hold the other piece in place.) Cold chisels are made of steel and have a variety of shapes at the end (nose); these noses are useful for a variety of purposes.

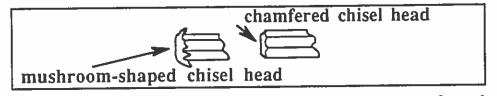

It is important to be safe while using chisels: (1) When pounding a chisel, it is a good idea to use a chisel holder – this allows the machinist to keep fingers out of the way; (2) keep the chisels sharp, so they cut well; (3) keep the top of the chisel chamfered – if the top is shaped like a mushroom, pieces of metal can fly off when you pound the chisel; (4) remember to wear your safety glasses.

PUNCHES: A punch is made of steel and has a sharpened point. The machinist uses a punch by putting the point on a workpiece and hitting the other end with a small ball-peen hammer. A small dent is made when the chisel is hit. The prick punch has a sharp point (30o) and is used to mark layout lines on a work-piece. (The layout lines tell the machinist where to cut the drill to make the part.) The center punch has a point with a wider angle (90o) and is used to mark where the centers of holes are. The center punch makes a wider dent than the prick punch; the point of a drill will fit more easily into a center punch dent.

MULTIPLE-CHOICE QUESTIONS

Tool Names

Tool Identification

Spelling

Tool Identification and Spelling

End-of-Lesson Questions Part A: Listening

Part A: Look at the pictures. Listen to the tool names on the recording. Type the letters in the spaces below.

Click here to listen to the recording.

End-of-Lesson Questions Part B: Writing