Lesson 3 Bench Grinders and Pedestal Grinders

Two Grinders

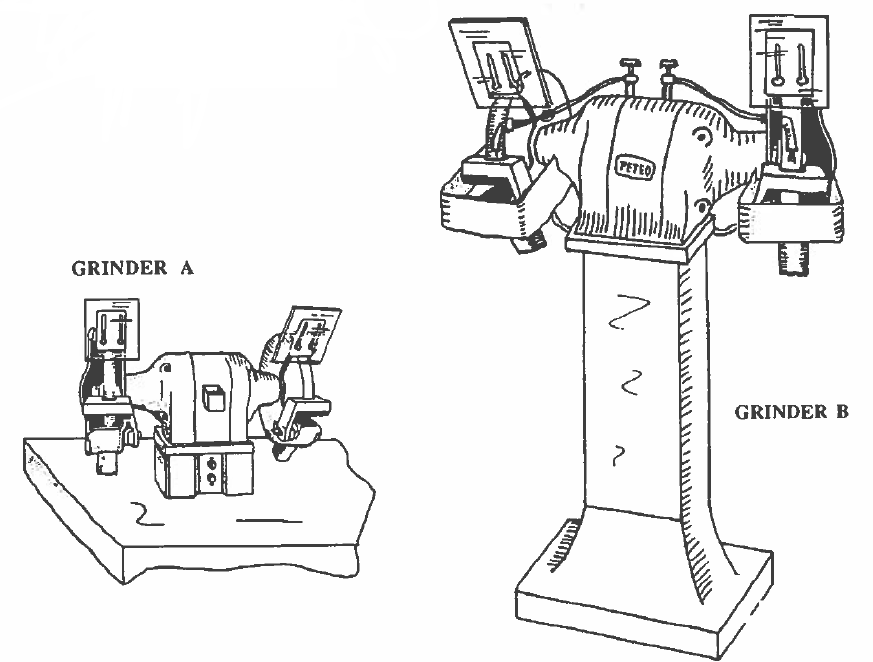

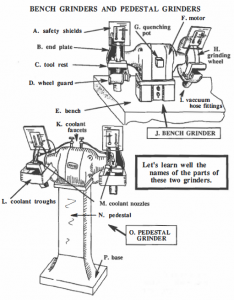

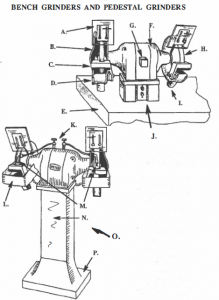

Look at the two grinders pictured below.

Now do the following:

There are many things which are the same on the two machines shown. Compare the two pictures, and then complete the exercises below.

Word List

| 1.) to fracture | to break a hard material into pieces. e.g., A very hard diamond is used to fracture the grains of abrasive. |

| 2.) to dress | to fracture or remove the grains of abrasive on the surface of the grinding wheel. e.g., Heraldo dressed the grinding wheel when the surface grains became dull. |

| 3.) to true | to remove material from the surface of the grinding wheel to make it perfectly round. e.g., When the wheel loses its round shape, it must be true. |

| 4.) to reciprocate | to go back and forth repeatedly, first in one direction, then in the opposite direction. e.g., A table which moves back and forth repeatedly is called a reciprocating table. |

| 5.) heavy-duty | strong and tough, made to keep operating even with great stress and extra work. e.g., A pedestal grinder is more of a heavy-duty machine than is the bench grinder. |

| 6.) lateral | having to do with the side of something. e.g., One of the tables moves in a lateral direction, from side to side. |

| 7.) loaded | the condition of a wheel’s grinding surface when it is filled with tiny chips. e.g., Igor, this grinding wheel is loaded; we’re going to have to dress it. |

| 8.) pedestal |

a bottom column which supports something above it. |

| 9.) tool crib | a special room for keeping tools which the workers can borrow when they need them. e.g., Make sure you sharpen your cutters before you return them to the tool crib. |

Spelling

Matching Definitions

GRINDING MACHINES

Before starting this lesson about grinding machines, please review Module 3, Lesson 9 in the sections that explain hand-held grinders, grinding wheels, and the abrasives and bonds that are used to make the wheels.

Purpose of Grinding: Machines: Grinding machines are used in the machine shop for finishing the surface of parts that have been previously cut and shaped on other machines, like a lathe or a mill. The machinist usually leaves .010 to .030 in. of material which must be removed by the grinding operation. By using different kinds of grinding wheels with different size grains of abrasive, the machinist can make finishes on parts that vary from a pattern of fine, arcing scratches to the smoothness of a mirror.

Another purpose of grinders is to sharpen toolbits, milling cutters, and other cutting tools that the machinist uses. It is important for every machinist to be able to sharpen his/her own tools. If the tools are from a tool crib that everyone uses, then the machinist will want to sharpen the tools after use, so the next worker can start out with sharp tools.

Various Grinders and How They Work: During lathe operations, the work spins and the toolbit is fed into and along the workpiece. During milling operations, the cutter rotates and the table feeds the work into the cutters by raising, by moving longitudinally, or by moving in or out fonn the column of the mill. During drilling operations, the rotating drillbit is fed into work secured on a stationary table. For grinding operations, a grinding wheel is rotated and meets the work in a variety of ways, depending on the kind of machine used:

Bench grinder: This small grinder, which is mounted on the workbench, is usually used for tool sharpening; the machinist must hold the tool in his/her own hand and feed it into the spinning wheel.

Pedestal grinder: This grinder is more heavy-duty than the bench grinder and stands aluPe on the shop floor, but its purpose is the same–to do tool sharpening and other small, quick jobs.

Surface grinder: This is a larger, stand-alone grinding machine of the same size as a lathe or a mill. The work is fed into the rotating grinding wheel by the movements of a table which moves back and forth longitudinally beneath the wheel. This reciprocating table is mounted on top of a second table which moves in or out laterally, in a direction perpendicular to the longitudinal movements.

Cylindrical grinder: This is also a larger, stand-alone grinder which puts a finish onto round work such as that which comes from a lathe; work is mounted on this grinder in ways similar to a lathe–usually between centers or in a chuck. A moving table which holds the spinning work is then fed into a stationary, rotating grinding wheel.

These are the main kinds of grinders. We will study bench grinders and pedestal grinders in this lesson; then we’ll have a separate lesson on surface grinders and another on cylindrical grinders.

All of these grinders use grinding wheels which remove material from the surface of a workpiece. It is the rough edges of the abrasive grains embedded in the wheel which cut tiny chips of material from the work.

With use, the cutting edges of the grains become dull and the spaces between the grains can become filled, or “loaded,” with tiny metal chips and dust; then the wheel is less efficient in its cutting. With use the shape of the wheel may also not be truly round anymore. When this happens, it is necessary to true and dress the grinding wheel:

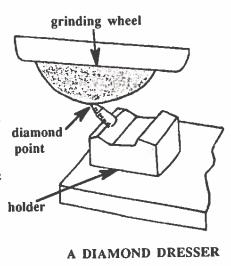

Truing a wheel: This is done by grinding away enough of the wheel surface to make the wheel concentric with the spindle axis. This is done with a special diamond-pointed tool which is hard enough to remove grains of abrasive.

Dressing a wheel: This is done with the same diamond-pointed tool. called a diamond dresser. This relieves the problems of a dull and loaded wheel by fracturing the surface grains to make new sharp edges or by removing the dull surface grains and exposing new ones beneath them. An industrial grade diamond (not gem quality) is mounted in a holder, and the wheel is rotated against the diamond point for the truing and dressing.

The best preventive step to avoid loading the wheel is to use a good supply of coolant during the grinding operations.

Matching

LET’S SEE WHAT YOU KNOW ABOUT GRINDING MACHINES:

Short-Answer

Fill-in-the-Blank

BENCH GRINDERS AND PEDESTAL GRINDERS

Word List

| 1.) attendant | a worker who is in charge of a special place with special services. e.g., The tool crib attendant makes sure that all the tools have been sharpened and returned. |

| 2.) to deflect | to tum something in a different direction. e.g., The shield is able to deflect flying chips away from the machinist’s eyes. |

| 3.) to dip | to put something into a liquid and then quickly take it out. e.g., Ramon dipped the heated part into the cold water. |

| 4.) to float | to cause to ride on, or near, the surface of a liquid. e.g., The chips from grinding float away in a spray of coolant. |

| 5.) to suck | to draw in liquid or air. e.g., Rudolfo and Mimi used to suck coca cola from the same can. Related Word: suction = the act or process of sucking. |

| 6.) fitting | a small part used to join other parts together. e.g., That pipe on the grinder is a fitting for putting on a vacuum hose. |

| 7.) performance review | the act of evaluating how well a worker is doing his/her job. e.g., Mick had a performance review with his supervisor after one month at the shop. |

| 8.) pinch point | any place on a machine where a rotating part could catch a worker’s clothes, hair, or fingers. e.g., A pinch point on a grinder is the spot where the spinning wheel touches the work. |

| 9.) trough | a long, open container for catching or holding liquid. e.g., This grinder has a trough to catch the used coolant dripping off the part and the wheel. |

| 10.) vacuum | a space with nothing in it, a space with less pressure in it than outside it. e.g., A vacuum machine pumps air out of a space and allows something else to be sucked into that space. |

Spelling

Cloze

Same meaning (Synonyms)

BENCH GRINDERS AND PEDESTAL GRINDERS

The bench grinder and the pedestal grinder are found in many shops. They are not complicated machines and are very useful for sharpening tools and other small jobs in which the machinist holds something and feeds it into a grinder by hand. Let’s look at these machines more closely.

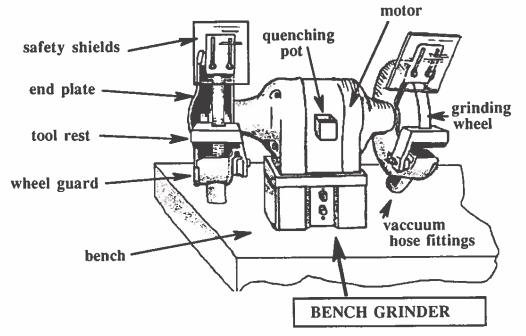

The Bench Grinder: Here is a picture of a typical bench grinder, along with its main parts. Study the parts and their names.

Safety shields: These pieces of plastic are on the machine to protect the eyes of the machinist by deflecting any sparks, chips, dust, or broken parts. When they are positioned correctly, the machinist will be looking through the plastic shield at the point where the grinding is taking place. Notice that the bench grinder has two grinding wheels. (In the picture, the shields are pushed back from the position, farther forward, where they would be if work was being done.)

End plates and wheel guards: The wheels are both covered by metal guards which protect the machinist and anyone else in the shop from accidently touching the spinning wheel or from being hit by flying

particles (in case the wheel or the work breaks and goes flying in all directions). The end plates complete the casing around the wheels.

Motor, grinding wheels, and quenching pot: The grinding wheels are turned by a strong motor. Wheels of various shapes and abrasive grain sizes can be mounted on the bench grinder; wheels of two different grain size could be used on the same machine. Because a bench grinder has no source of coolant, the machine has a small quenching pot with water in it for dipping the tool whenever heat starts to build up because of the friction between the tool and the grinding face of the wheel. Tools can not be held by hand, unless they are quenched frequently.

Tool rest: In front of each grinding wheel is a metal bar on which the machinist can rest the tool while grinding. The tool rest gives more support and greater accuracy by steadying the part being ground.

Vacuum hose fittings: As the wheel turns, tiny chips of the grinding are thrown back into the housing formed around the wheels by the wheel guards and the end plates; at the bottom of that housing there is a vacuum hose fitting for each wheel. If desired, vacuum hoses can be fitted on and the chips will be carried away by vacuum suction. If the hoses are not used, then the chips will simply fall out onto the floor.

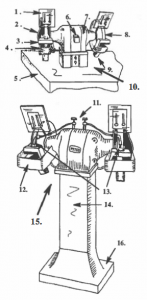

Identify Parts of Bench Grinder

Matching Definitions

BENCH GRINDERS AND PEDESTAL GRINDERS (Continued)

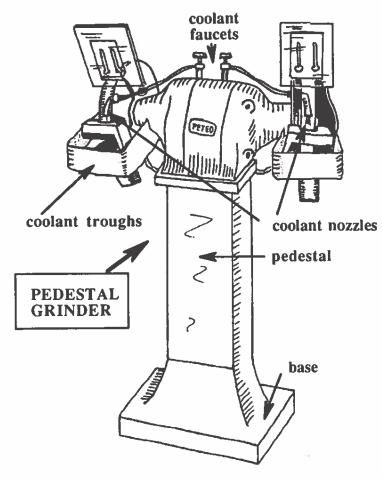

The Pedestal Grinder: Below is a picture of a typical pedestal grinder, along with its main parts. The pedestal grinder gets its name from the heavy-duty pedestal on which it stands alone. It is good for the same jobs that are done on the bench grinder, but it is bigger and stronger. Another difference is that the pedestal grinder is equipped with a system for spraying coolant onto the point where the tool is being ground. Let’s look at the parts more closely.

Coolant nozzle: These nozzles can be aimed at the spot where the work meets

the grinding wheel. This fluid is the same as the cutting fluid which we studied when we looked at the lathe, but here it is used primarily for its ability to cool rather than to lubricate.

Coolant trough: The troughs are in place to catch the coolant and some of the chips that float in it and return them to the coolant system to be pumped through agam.

Coolant faucets: The faucets allow the machinist to turn the flow of coolant on or off as needed.

You will further notice that the rest of the parts in the picture are very similar to those in the picture of the bench grinder: safety shields, tool rests, motor, wheel guards, end plate, and vacuum hose fittings

Grinder Parts Chart

Conversation Practice:

Situation: Raul, a supervisor, is talking with Mick, a machinist who has been working at the shop for one month.

Raul: Mick, I want to do a performance review with you today. There are some things I want you to improve.

Mick: Go ahead. What should I do differently?

Raul: The main thing is safety. I’m concerned about your safety around the grinders and all the heavy machinery with pinch points.

Mick: What’s a “pinch point”?

Raul: That’s a place where there are rotating parts which can grab hold of a sleeve, or long hair, or a finger, or a jacket, and pull you into the machine.

Mick: Thanks for telling me, but I thought I had been pretty careful around the machines.

Raul: What worries me is when you start talking to other people while you’re working. You distract them, and you’re not concentrating on the work. That’s when an accident could happen.

Mick: Okay. Anything else?

Raul: Yes, the tool crib attendant tells me your tools are usually not sharpened when you return them. I want you to take the extra time to go over to the pedestal grinder and sharpen them, before you turn them back in.

Mick: Okay. What else?

Raul: Those are the two things I'<l like you to work on. Other than that, your production has been increasing, and you rarely make scrap. Those are both good signs. Keep up the good work!

Mick: Thanks, Raul. I like working here, and I’ll try to do better.

Grinders parts vocabulary

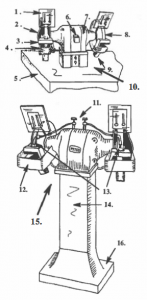

Identification of Bench and Pedestal Grinder Parts

Additional Reading in the Textbook

The machine shop textbook, Technology of Machine Tools, was introduced in the last lesson. In this lesson you have started to learn about grinding and grinders. The textbook can give you much additional information on this topic.

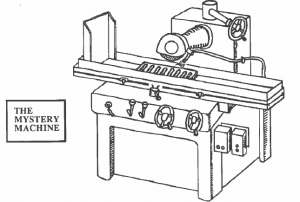

The Mystery Machine

Not everyone knows what machines are used in the machine shop. It might be fun to see what names students in your class would give to a machine that they may have never seen.

Questions:

A.) What name would you give this machine?

B.) What is it used for?

Share your answers with classmates.