Lesson 4B Adapter and Shank-Type Milling Cutters

MILLING CUTTERS

Adapter and Shank-Type

Word List

| 1. adapter | any device for connecting things that would not ordinarily fit together. e.g., Some cutters require an adapter before they can be attached to the spindle. |

| 2. collet | a metal sleeve used for holding shank-type tools. e.g., The end mill, which looks like a drill, fits into a collet. |

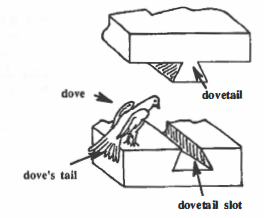

| 3. dovetail |

a triangle shaped parts that fits into a cut-out space (slot) of the same shape. The two fit together tightly. The part is called a dovetail because it looks like a dove’s tail. |

| 4. dull | not sharp, not able to cut because of wear. e.g., The machinist must always be sure to sharpen any dull cutters before using them. |

| 5. hollow | having an empty space inside. e.g., A football is hollow; there is nothing but air inside. |

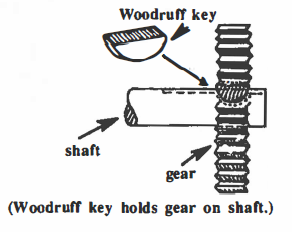

| 6. key | a piece put into a hole or space to lock or hold parts together. e.g., A gear will not slip on a shaft if it is held in place with a key. Related words: key seat = the groove or slot where the key fits in place; keyway = the same as keyseat. |

| 7. set screw | a small screw used to hold something in place. e.g., The toolbits are held in the adapter by tightening set screws. |

| 8. solid | having one piece without breaks or divisions. e.g., A flycutter has at least three separate pieces: an adapter, a toolbit, and a set screw; but the dovetail cutter is one solid piece. |

| 9. spot | a certain place or location on a larger body. e.g., “Honey, there’s a spot on my back that itches–can you scratch it, please?” |

Spelling

Word Find

MILLING CUTTERS

Adapter and Shank-Type

Reading Information

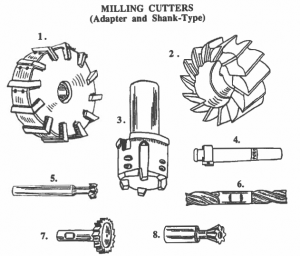

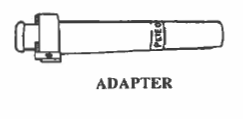

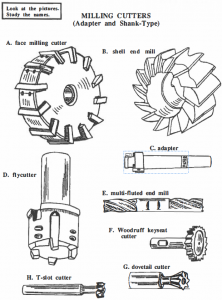

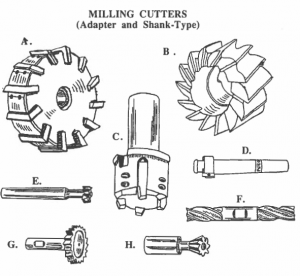

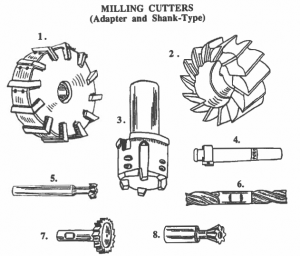

A second kind of milling cutter is not mounted on an arbor; rather, it is mounted on an adapter or is made in one solid piece with a shank at one end and the cutting teeth at the other end. With an adapter or shank, the cutters can be used in either a horizontal mill or a vertical mill. Vertical mills will take only adapters or shank-type cutters. The shanks of these cutters can be either tapered or straight. Let us look at these cutters.

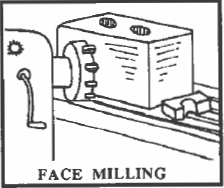

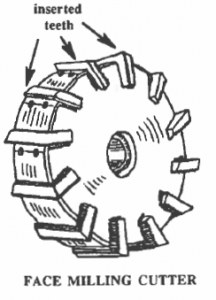

1. Face milling cutter: This is a large, heavy cutter which is more than six inches in diameter and has teeth inserted in the periphery; these teeth can be made of high speed steel or tipped with carbide. This type of cutter is usually mounted on an adapter which is put into the spindle of a horizontal mill; the face of the mill will remove large areas of surface material when the work is fed into the cutter.

these teeth can be made of high speed steel or tipped with carbide. This type of cutter is usually mounted on an adapter which is put into the spindle of a horizontal mill; the face of the mill will remove large areas of surface material when the work is fed into the cutter.

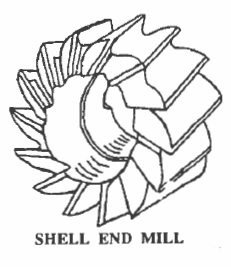

2. Shell end mill and adapter:

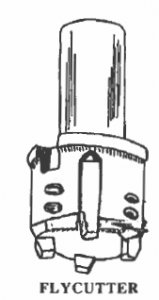

3. Flycutter: The flycutter is made up of a special adapter which can hold one or more toolbits, just like those used on a lathe. A flycutter is a good tool because the toolbits can be ground to any shape the machinist wants and because it is inexpensive to replace the toolbits when they wear out or when a diffetent shape is desired. The toolbits are held in place by the tightening of set screws which are screwed in to press on the inserted toolbits.

The flycutter will cut out an entire path of material when the work is advanced perpendicular to the axis of the cutter1s rotation.

4. End mills: These cutters look like drills; they can have two flutes or more than 2 flutes (e.g., 3 flutes, 4 flutes, 10 flutes, etc.); when they have more than two flutes they are called multi-fluted end mills. Each mil has two ends, but only one end is used at a tune; the other end 1s fitted into a collet which holdsthe cutter; this second end is saved in sharp condition for use when the first end becomes dull. So the end mill is two tools in one. End mills are used for cutting slots of different sizes and in different locations.

The end mill gets its name from the fact that it has cutting teeth on the end of the mill as well as on the periphery. The flat spot shown in the middle of the shank is there so that a set screw can be tightened against that spot to hold the shank in place.

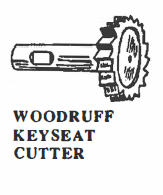

5. Woodruff keyseat cutter: This cutter has a solid shank and straight teeth. It is good for cutting the keyway (keyseat) where a Woodruff key will go. This key and keyseat are designed to hold a gear in place at the end of a shaft.

5. Woodruff keyseat cutter: This cutter has a solid shank and straight teeth. It is good for cutting the keyway (keyseat) where a Woodruff key will go. This key and keyseat are designed to hold a gear in place at the end of a shaft.

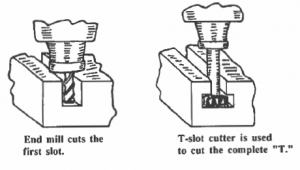

6. T-slot cutter:

This cutter is used to cut the anns of the 0T” after a vertical slot has been cut into the material by the use of an end mill. The T-slot cutter is really a small side milling cutter with teeth on both sides and on the periphery of the cutter. It is one solid piece with teeth and shank together. As with many of these cutters, the shank can be tapered or straight.

The first picture on the left, an end mill is used to cut a slot in the workpiece–this is the vertical stroke of the “T”.

In the second picture, the T-slot cutter is used to cut the two arms of the “T.”

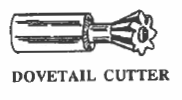

7. Dovetail cutter:

A dovetail is used in woodworking and in metal work as a way to hold two pieces together; it is called dovetail because the shape looks like a dove’s tail. The dovetail cutter is one piece with a solid chank and cutting teeth set at an angle of 45, 50, 55 or 60 degrees. Like the T-slot cutter, the dovetail cutter is used only after the center section of the cut has first been made with an end mill.

A dovetail is used in woodworking and in metal work as a way to hold two pieces together; it is called dovetail because the shape looks like a dove’s tail. The dovetail cutter is one piece with a solid chank and cutting teeth set at an angle of 45, 50, 55 or 60 degrees. Like the T-slot cutter, the dovetail cutter is used only after the center section of the cut has first been made with an end mill.

H5P tool for dictation? Ex. 8.50

Scripts

LISTENING AND WRITING WITH A PARTNER

QUESTIONS from Partner No. 1 (You)

Directions:

- Keep this page and write in the spaces below.

- Give the next page to a partner you choose or to the class room aide. (That page has the answers which you wfll write.)

- Read the following questions one-at-a-time to your partner. l bttcz: carefully te the answers.

- Write down the answers exactly as your partner says them. You can ask your partner to repeat.

QUESTIONS:

- What does a face milling cutter look like?

- If a face milling cutter has less than a 6-inch diameter, what is it called?

- Why is a flycutter a useful tool?

- Where are the cutting teeth located on an end mill?

- What is the purpose of a Woodruff key?

- What two tools are used to cut a T-slot?

- At what angles can you cut a dovetail slot?

- How do you attach a shell end mill to the spindle?

- What kind of cutters can be used in a vertical mill?

LISTENING AND WRITING WITH A PARTNER

ANSWERS from Partner No. 2

Directions:

- The student you are with will ask you some questions.

- The ans ♦1er 9 to those questions are written on this page.

- After each question, read the answer slowly, so the student can write it down. The student may ask you to repeat.

- That’s OK.

- When you are finished, help the student check the spelling of the words and the completeness of the answers.

ANSWERS:

- A face milling cutter is a large wheel with strong, steel teeth inserted into its periphery.

- It’s called a shell end mill.

- A flycutter is useful, because it uses inexpensive toolbits which can be ground to whatever shape is needed.

- The cutting teeth on an end mill are located at the ends and on the periphery.

- A Woodruff key is used to hold a gear on the end of a shaft.

- To cut a T-slot, you should use an end mill and a T-slot cutter.

- A dovetail slot can be cut at 45, 50, 55 and 60 degrees.

- You must mount it on an adapter which you then fit into the spindle.

- Any cutter with a shank or which can be mounted on an adapter can be used in the vertical mill.

Note: Use these answers to check the student’s writing.

Spelling

Matching Cutter Names

Spelling with missing letters

Identification