Lesson 3 Main Parts of Vertical Milling Machine

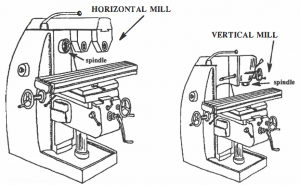

Two Kinds of Milling Machines: Horizontal and Vertical

Compare Machines

need arrows in H5P

THE MAIN PARTS OF A VERTICAL MILLl1’lG MACHINE

Word List

| 1.) expensive | costing a large amount of money as compared with something cheaper. e.g., Her fur coat was very expensive. |

| 2.) to look like | to be have a similar appearance. e.g., Sheila looks like her sister, except her hair is longer. |

| 3.) model | a kind of manufactured product which has features that make it different from other products of the same kind. e.g., The Ford Company makes many kinds of autos: some models are expensive–others are cheap. |

| 4.) to mount | to put something in its correct place. e.g., The street lights are mounted on top of high poles in order to give more light. |

| 5.) quill | a hollow tube which acts as a housing around the spindle. e.g., The quill of the ram-type mill will move 3 or 4 inches for the purpose of drilling. (picture of feather quill) |

| 6. ) rather than | instead of, in the place of. e.g., I will work in two jobs rather than see my children go hungry. |

| 7.) shift | a period of time for working after which other workers come to continue the work. e.g., Some companies divide 24 hours into three 8-hour work shifts:

DAY (7 a.m. to 3 p.m.), SWING (3 p.m. to 11 p.m., and GRAVEYARD (11 p.m. to 7 a.m.). |

| 8.) to stick out | to be farther out than something else. e.g., The state of Florida sticks out into the Atlantic Ocean. (image map of Florida) |

| 9.) tough | not easily broken; able to be used often without wearing out. e.g., These pants are made of very tough material. |

| 10.) to traverse | to go back and forth over something–first in one direction and then in the opposite: bidirectional. e.g., The mill’s table can be made to traverse its length many times in a day. |

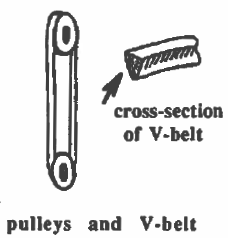

| 12.) V-belt |  a closed belt used to drive pulleys; a cross-section is shaped like a “V.” a closed belt used to drive pulleys; a cross-section is shaped like a “V.”e.g., The mill’s motor drives the spindle by the use of V-belts inside the toolhead. |

| 13.) well-suited | made well for some particular purpose. e.g., A spoon and a large bowl are well-suited for eating ice cream. |

Spelling

Word Find

PERIODS FOR WORKING

Many companies in the United States who do manufacturing run their operations during all 24 hours of a day. In order to keep the production going, the company hires many workers and divides the day into three shifts: Workers who work from 7 a.m. to 3 p.m. are the day shift; those who work from 3 p.m. to 11 p.m. are the swing shift; and those who work from 11 p.m. to 7 a.m. are the graveyard shift.

Sometimes people who work swing or graveyard are paid more money because it is more difficult to work at night. Sometimes new workers are given the night-time shifts, so the workers who have been at the company longer can have the good day-time jobs. The practice of giving special things to those workers who have been the longest time at a company is called seniority.

If a worker stays longer than their eight-hour shift, the worker may be paid extra money for overtime. Overtime is work done in addition to a regular eight-hour shift. Sometimes overtime hours are paid at a higher rate than regular time–sometimes at time and a half or double time. The words “time and a half’ mean the worker is paid 1½

times his regular pay for each hour of work.

For example, if a worker hourly pay is $10, they would receive $15 for each hour of overtime.

Shift Identification

A Little Overtime Calculation

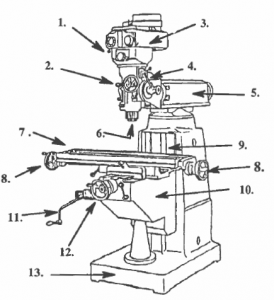

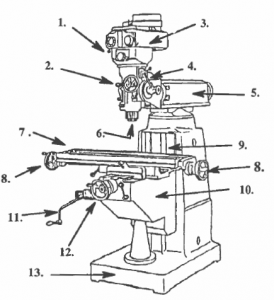

THE MAIN PARTS OF A VERTICAL MILLING MACHINE

(Ram-Type)

Spelling

Reading Information

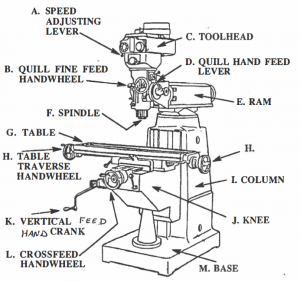

THE MAIN PARTS OF A VERTICAL MILLING MACHINE

(Ram-Type)

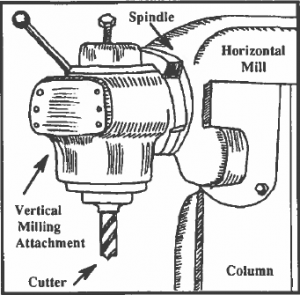

The best way to do many milling operations is to use a vertical mill, i.e., a mill that uses a cutter which rotates around a vertical axis rather than around a horizontal axis. There are several ways to get this vertical rotation.

1. Vertical milling attachment: The first way to get vertical rotation is by mounting a vertical attachment on the spindle of a horizontal mill. This attachment changes the direction of the rotation by 90° from the horizontal position which we have seen. Some models of the vertical milling attachment are able to swivel which allows boring , drilling, and other operations at angles up to 45° away from the vertical position.

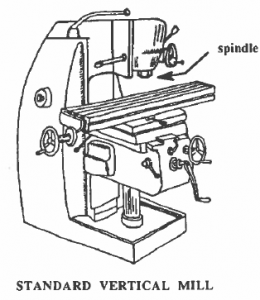

2. Standard vertical milling machine: This machine looks just like the horizontal machines we have already seen, except, instead of a horizontal spindle, an overarm, and arbor supports, it has a spindle mounted in a vertical position.

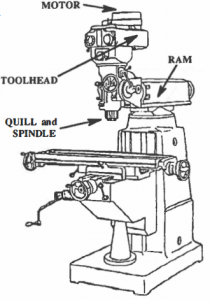

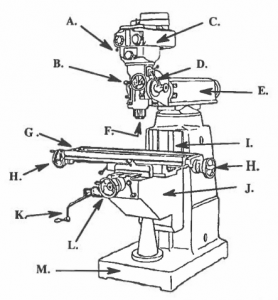

3. Ram-type vertical milling machine: This type is shown in the main pictures of this lesson. It has a ram which projects the spindle out over the table;  the ram is really a turret that will swiveJ on the top of the column. Mounted at the end of the ram is the toolhead; inside the toolhead is a mechanism of V- belts which drives the spindle; these belts are, in tum, driven by a motor mounted on top of the toolhead.

the ram is really a turret that will swiveJ on the top of the column. Mounted at the end of the ram is the toolhead; inside the toolhead is a mechanism of V- belts which drives the spindle; these belts are, in tum, driven by a motor mounted on top of the toolhead.

The spindle is placed inside a tube shaped housing called the quill. Most of the time, the work is fed into the cutter by the raising of the table; however, when the vertical mill is used for dril ling, the quill can be used to feed the cutter into the work–the quill will move up and down 3 or 4 inches. This quill movement is controlled by a quill fine feed handwheel and by a quill hand feed lever.

The other parts of the ram-type vertical mill are like those in the horizontal mill: a knee which travels up and down the column to raise a table into the rotating cutter and a variety of hand-wheels, levers, and cranks to control various feeding motions.

This ram-type vertical mill is small, tough., and well-suited for many milling jobs. The cutters for this machine are not as expensive as some used on horizontal mills.

Ex: 8.28 pg 12 Dictation?

Write down the three ways that a machinist can get the vertical rotation of a cutter to do vertical milling.

1.)

2.)

3.)

Comprehension Chec

Identification

Spelling with missing letters

Identification

Situation: Joanne, an experienced supervisor, is talking with Matt, a new worker.

Conversation No. l:

Joanne: Matt, I want you to spend this shift learning about this vertical mill.

Matt: I worked on a vertical mill the other day, but it didn’t look like this one.

Joanne: That’s right. That was a standard mill–this is a ram-type mill.

Matt: What’s the difference?

Joanne: This one has a ram that projects the spindle out over the table. That ram swivels on the top of the column–just like a turret.

Matt: I see. The ram is that part that sticks out. I’m very excited to learn how to use this machine.

Conversation No. 2:

Matt: Tell me some other things I should know about this ram-type mill.

Joanne: The spindle, as you can see, rotates around a vertical axis and not a horizontal one.

Matt: That’s why it’s called a vertical mill, I guess.

Joanne: Yes, that’s correct. Now let me tell you about a couple other parts: That’s the motor on top underneath that housing. It drives the V-belts that tum the spindle.