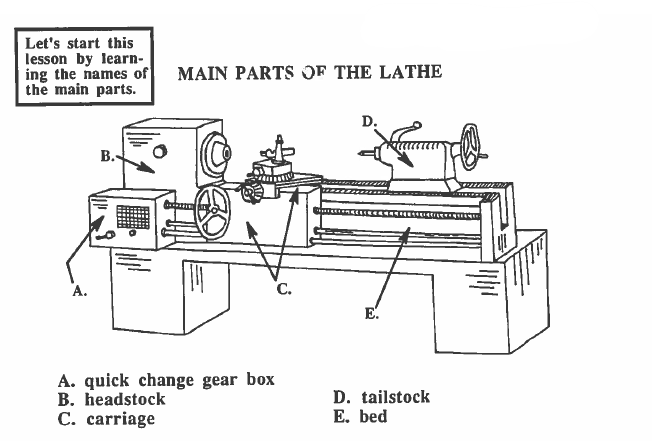

Lesson 2 Main Parts of the Lathe

BEFORE WE BEGIN THIS LESSON

Look ahead at the information that follows. Do the following:

MAIN PARTS OF THE LATHE

MAIN PARTS OF THE LATHE

MAIN PARTS OF THE LATHE

Word List

| bearing |

|

| to transmit |

to send from one place to another; to pass along. E.g., The motion of the rotating shaft is transmitted to the workpiece. |

| device |

a mechanical invention made for some purpose. E.g., A telephone is a very useful device, when you live outside the city. |

| to support |

to carry or bear the weight of something. E.g., The drunken man was supported by a friend, as they walked from the bar. |

| chemical composition |

the kinds of chemicals that are in something. E.g., The chemical composition of alloy steel is iron along with chemicals like carbon and titanium to give it strength. |

| to revolve |

to turn in a circular motion around an axis, to rotate. E.g., The earth revolves around the sun. Related word: revolution = one complete turn of 360o. |

| RPM |

abbreviation for revolutions per minute. E.g., RPMs are used to measure the speed with which something rotates. |

| to advance |

to move forward. E.g., The cutting tool advances along the workpiece as it cuts away more material. |

| locker |

a metal closet or compartment that can be fastened with a lock. E.g., Many companies have lockers in which employees can store their personal things. |

| to be in place |

for something to be located in the correct place. E.g., All Kim’s tools were in place inside the tool cabinet. |

| to drag |

to pull along in a rough manner. E.g., Joe and Beth dragged the power saw across the room. |

| lever |

a handle which transmits pressure or activities a switch when you press or pull it. E.g., Some lathes have many levers as part of their controls. |

| handwheel |

a wheel at the end of a shaft used to turn that shaft and control some activity. E.g., The steering wheel in an automobile is a good example of a handwheel. |

| lathe spindle |

a shaft-like part that rotates while holding the thing to be turned (live spindle), or a similar part that does not rotate (dead spindle). E.g., Any lathe spindle rotates around its axis. |

| by hand |

something done, not with machines, but with hands. E.g., These straw hats were all made by hand. |

Vocabulary Practice

|

Congratulations! You’re doing very well and you’re on your way to becoming a machinist!

|

THE MAIN PARTS OF THE LATHE

Now it’s time to learn more about the lathe. What are the main parts of the lathe? What new words will you need in order to talk about the lathe and ask questions? Let’s study these main parts.

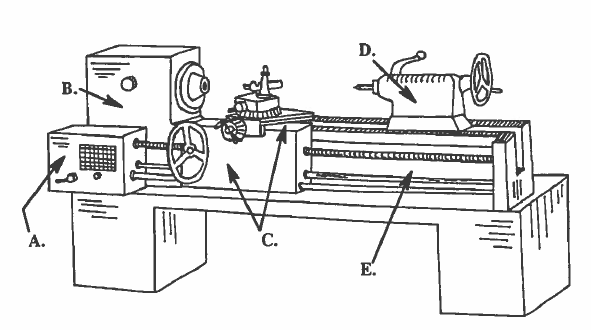

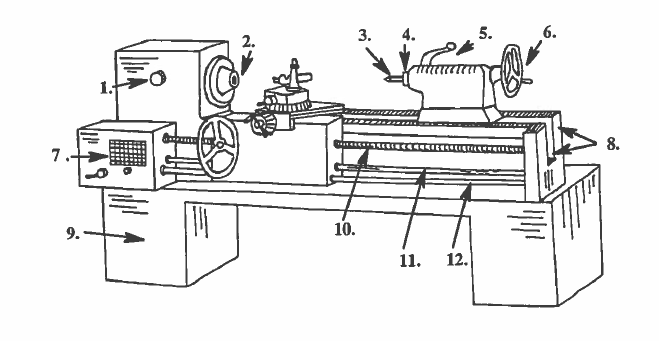

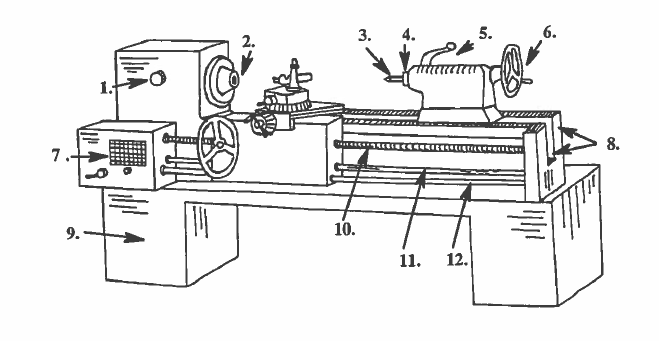

The main parts of the lathe are: (1) the bed, (2) the quick-change gearbox, (3) the headstock, (4) the carriage, and (5) the tailstock.

1. The bed: is the strong cast metal part which runs the length of the lathe and which supports the other main parts. The bed has a track, called the ways, which is cut into the top of the cast metal. Several other parts of the lathe can move along these ways, e.g., the carriage, and the tailstock.

2. The quick-change gearbox: is a box on the left-hand side of the machine; it contains several different sizes of gears that turn the feed rod and the lead screw at a variety of speeds; these two parts move the carriage with its cutting tool into the spinning workpiece to make the desired cuts.

3. The headstock: is also located on the left-hand side of the lathe. Inside the headstock are other gears or a belt-and-pulley system which drives the headstock spindle. This spindle is free to turn because it is held in place by bearings. The headstock spindle is what transmits the spinning motion to the workpiece; the left-hand end of the workpiece is held by a variety of work-holding devices which attach the work to the spindle.

4. The carriage: is free to move in any direction, and its motions will be determined by the requirements of the cutting job. The carriage holds the cutting tool steady and moves it into the work. We will learn more about this part of the lathe in part 4.

5. The tailstock: can be located and locked in place anywhere along the bed of the lathe. It also has a spindle, the tailstock spindle, whose job is to hold up the right-hand side of workpiece, as it spins. The tailstock spindle does not hold and spin the work; it only supports it. Because of this difference, the tailstock spindle is said to have a dead center and the headstock spindle is said to have a live center.

Descriptions of Main Parts of Lathe

Additional Information

Speed, Feed, and Depth of Cut for Engine Lathes

A lathe is a wonderful tool because for the variety and precision of the machining jobs that it can do. The lathe can only do what its operator makes it do; therefore, every machinist needs to learn about the lathe and practice operating it until he or she becomes highly skilled. Among the important ideas used in successfully operating the lathe are these: speed, feed, and depth of cut.

1. Speed: there are two uses of the word speed in using a lathe

a. spindle speed: The spindle speed is the number of times a point on the circumference of the headstock spindle turns a full circle (or revolution) in one minute. Therefore, spindle speed is measured in revolutions per minute (RPMs). This speed is measured in RPMs, whether there is a workpiece on the spindle or not.

b. cutting speed: The CS (cutting speed) is not measured in RPMs, but in feet per minute or meters per minute (for metric lathes). CS is the number of feet of the workpiece circumference which passes the edge of the cutting tool in one minute. For example, when a machinist says the lathe is set to CS of 60 ft./min. (feet per minute), he/she means that 60 feet of the workpiece circumference passes the cutting tool in one minute.

The cutting speed of a lathe is variable, i.e., the lathe can be set to turn the work faster or slower. Some metals can be turned at a higher CS than others, depending on their chemical composition hardness. The machinist must find the correct speed for a particular job. If the CS is too fast, the tool’s cutting edge will quickly break down; if the CS is too slow, the number of completed parts goes down and the company loses money.

To help the machinist decide which cutting speed to use, tables are given for various kinds of material used to make the cutting tools. Some of the common materials used to make tool bits (the cutting part of the lathe) are: high speed steel, cemented carbide, and ceramic.

2. Feed: When a lathe is operating, a round workpiece is spinning and a cutting tool is moving into the work; the tool edge removes chips of metal as it cuts into the circumference of the work. the cutting tool is also advancing down the length of the work, as the lead screw or the feed rod moves it along.

So, we see there are two feed motions:

a. tool feed (or depth of cut): this motion moves the tool in toward the center of the work, as it cuts chips from the circumference.

b. lathe feed: this motion advances the carriage (and the tool) down the length of the work; lathe feed is the distance the cutting tool moves along the length of the workpiece during one complete turn of the spindle. The feed is measured in inches or millimeters (mm). For example, in one RPM of the spindle, the cutting tool might advance along the workpiece a distance .025 in.; the feed on the machine would be set for .025 of an inch.

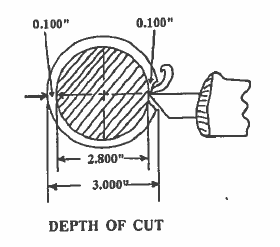

3. Depth of cut: Let’s look more deeply at the tool feed we spoke of above. This tool feed motion is better known as depth of cut. Depth of cut is the depth of the chip which the cutting tool removes. The depth of cut is measured in inches or millimeters. When the tool makes this cut, it removes material from all around the circumference of the workpiece. For example, if the depth of cut were .100 inches, the diameter of the workpiece would actually be reduced by .200 in., i.e. .100 in. from each side.

3. Depth of cut: Let’s look more deeply at the tool feed we spoke of above. This tool feed motion is better known as depth of cut. Depth of cut is the depth of the chip which the cutting tool removes. The depth of cut is measured in inches or millimeters. When the tool makes this cut, it removes material from all around the circumference of the workpiece. For example, if the depth of cut were .100 inches, the diameter of the workpiece would actually be reduced by .200 in., i.e. .100 in. from each side.

To summarize:

spindle speed = number of spindle revolutions in one minute.

lathe speed = the number of feet of the work’s circumference that pass the cutting tool’s edge in one minute.

lathe feed = number of in. the tool advances along length in one RPM.

depth of cut = depth of chip in inches.

Speeds, Feeds, and DOC

MORE TALK ABOUT LATHE SAFETY

Conversation No. 1: Isidro is talking with Alejandro.

|

I: |

Tell me some more about lathe safety, Alejandro. |

|

A: |

Well, Isidro, it’s better if we both practice safety, rather than talk about it, but here are some other things you should know. |

|

I: |

I’d like to hear them. |

|

A: |

I notice you’re wearing a watch and a long-sleeve shirt. Do you know that anything that hangs on you or off you – watches, rings, long sleeves, long hair, necklaces – that stuff – it can get caught in some of the revolving parts, and you can be pulled into the machine. |

|

I: |

I’ll take off this watch, and I’ll get my short-sleeve shirt from the locker. |

Conversation No. 2: The two men continue their conversation.

|

A: |

Let me show you a couple other things about safety on the lathe. |

|

I: |

Go ahead. I want to learn it all! |

|

A: |

Look at these metal plates that cover the gears in the headstock. There are several safety guards like that on the lathe. You should always make sure they’re in place before you start the machine. They keep you and your clothes from being dragged into the machine. |

|

I: |

That’s like what we talked about before. I need to be careful that none of my clothes or anything else gets caught in the machine. |

|

A: |

Do you see all those controls on the machine? There’s an ON/OFF switch, different buttons, levers and handwheels. You need to learn about them so you can control the machine. Don’t turn on the machine, until you understand what you’re turning on and how the control work. |

|

I: |

I hope you’ll teach me all of them. |

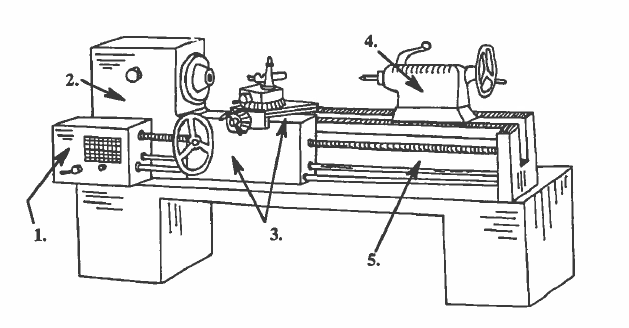

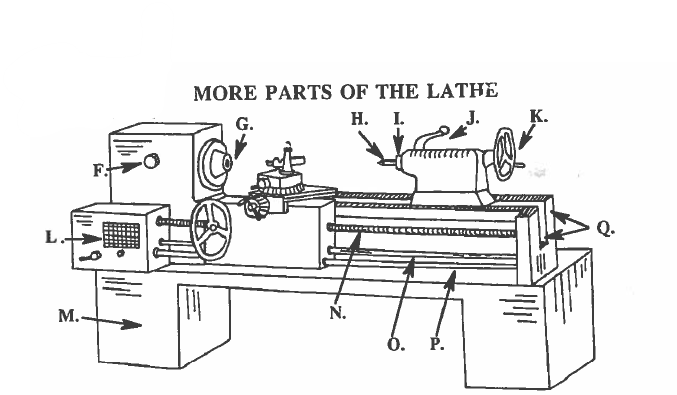

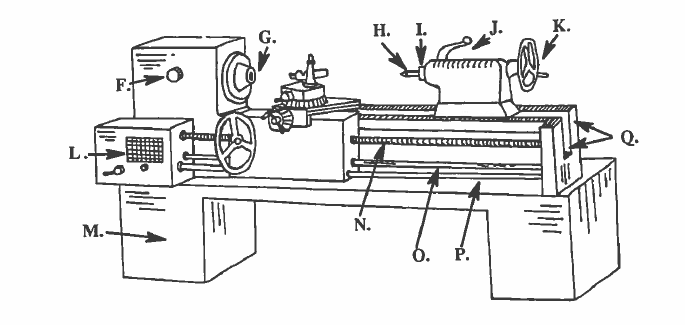

| F. RPM Dial | L. feed-setting chart |

| G. headstock spindle | M. base |

| H. dead center | N. lead screw |

| I. tailstock spindle | O. feed rod |

| J. tailstock spindle clamp | P. control rod |

| K. tailstock handwheel | Q. ways |

You have already seen many of these parts and learned what their purposes area as parts of the lathe. Now you can spend some time learning the names of these parts.

Note the tailstock handwheel. There are several handwheels of different sizes of most lathes; a handwheel is a device for moving some part of the lathe by hand; e.g., the tailstock handwheel will move the tailstock up and down the ways you turn the handwheel.

Notice also that the quick-change gearbox has a feed-setting chart attached to it. Its information will not be lost and can be easily read by the machinist.

Some other parts and their purposes: The tailstock spindle clamp is used to lock the tailstock spindle in a position so it will not move. The base has strong legs on which the bed and the other main parts of the lathe rest. The RPM dial on the headstock allows the machinist to change the speed of the headstock spindle.

Parts Identification

MORE PARTS OF THE LATHE

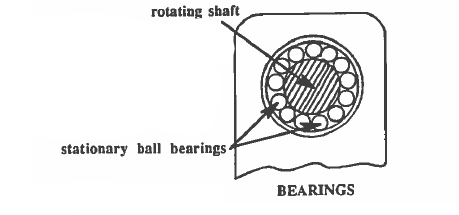

the part of a machine which supports any rotating arm, but allows it to turn freely. E.g., The rotating shaft in a motor is supported in bearings. Related word: to bear = to carry a load.

the part of a machine which supports any rotating arm, but allows it to turn freely. E.g., The rotating shaft in a motor is supported in bearings. Related word: to bear = to carry a load.