Introduction to Turning Machines aka CNC Lathes

OBJECTIVES

After completing this unit, you should be able to:

- Identify and describe parameters on CNC turning center (lathe)

- X and Z axes

- Point of origin

- Common quadrant

- Feedrate differences

- U and W words

- X value

- Constant Surface Speed application

CNC Lathes

For lathe programming, a lot of the codes and the variables are the same. For example, absolute and incremental positioning are the same on the mill and lathe.

However; there are many differences.

CNC Lathe Code Details that are different than mill codes.

X and Y axes on a lathe

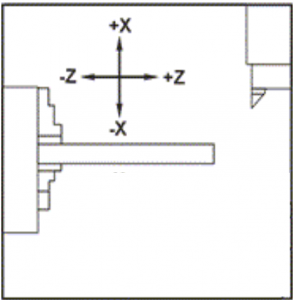

Cutting path for a lathe has the standard two axes: X and Z.

X is up and down

Z axis is left to right

Point of Origin: Zero is center of part.

Quadrants:

Most programing on the mill occurs in Quadrant IV.

On the lathe, Quadrants I and II are common.

Feedrate difference is a key issue:

Feedrates on mill = IPM, e.g. 8, 32, 54

Feedrates on lathe = IPR

On the manual engine lathe, F values are small because its inch per revolution.

On the CNC, Lathe F values should not be in whole numbers. e.g. .005, .006, .007

Z movement command relates to W

Review G90 and G91

Positioning in CNC Code

- G90, Z moves in cardinal numbers on line

- G91, Z moves based on previous position

On the FEMCO lathe, codes U and W to make adjustments. U is for X and W is for Z. There is an ability to use these codes. Sometimes, G90 is used.

Remember

A radial cut means the cut is only on side of the round part.

The total reduction is in the diameter.

X values on the lathe are different, too.

Lathe doesn’t program the x value intuitively.

X values are now diameter values. It’s a 2:1 ratio.

X = diameter value (not radius)

Count diameter values for features???

Another big change is with lathe headers.

Two types of lathe headers to choose with or without Constant Surface Speed – CSS.

(Details are in the next section of the book.)

Speaking of the header, just a heads up. There is no H code, no H word, on the lathe. The tool number captures the tool length offset or tool length compensation by using the offset number in the T code.

For example, T0101 Tool #1, Tool Offset #1

T0202, Tool #2, Offset #2.

And, so on.

(PIC)

X1, Z0

X1.5, z-.25

1.5, Z-.25

1..5 Z-3.0

X1.8, Z -3.0

X2, Z -3.1