Machine Movement

OBJECTIVE

After completing this unit, you should be able to:

- Identify the motions of a CNC machine

- Discuss the motions of a CNC machine

The Coordinate System Used in Computerized Numerical Control to Move Around a Part

In Computerized Numerical Control (CNC) machining, the part is on the table. Sometimes the table moves under the quill.

Sometimes, the table is fixed and the quill moves. The quill is another name for spindle. The quill holds the cutter.

When we talk of machine movement we will talk as if the table is fixed and the quill is moving. This quill movement can be in six directions.

Side to side

The quill can move from side to side. It moves left to right. In the X Y Z coordinate system, side-to-side movement is along the X axis. In English, speakers will say “back and forth”.

In and out

The quill can move in and out. This is cross movement. In the X Y Z coordinate system, cross movement is along the Y axis.

Up and Down

The quill can move up and down. This is vertical movement. In the X Y Z coordinate system, vertical movement is along the Z axis.

Remember in CNC machining, even if the table moves and the spindle is fixed, we are calculating the coordinates as if only the quill is in motion.

When the quill moves to the right, it is +X.

However, when the table moves to the right, the quill is moving in the -X direction.

When the quill moves to the left, it is -X.

However, when the table moves to the left, the quill is moving in the +X direction.

When the quill moves toward the front of the machine (the machine operator) it is -Y.

On the other hand, when the table moves toward the front, the quill moves in a +Y direction.

When the quill moves toward the back of the machine (and away from the machine operator) it is +Y.

On the other hand, when the table moves toward the column, the quill moves in a -Y direction.

When the quill moves down vertically, it is -Z.

But when the table moves down, it is a +Z movement.

When the quill moves up it is +Z.

But when the table moves up, it is a -Z movement.

Example: Vertical Milling Center (VMC)

MACHINE MOTION

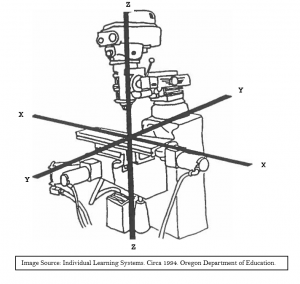

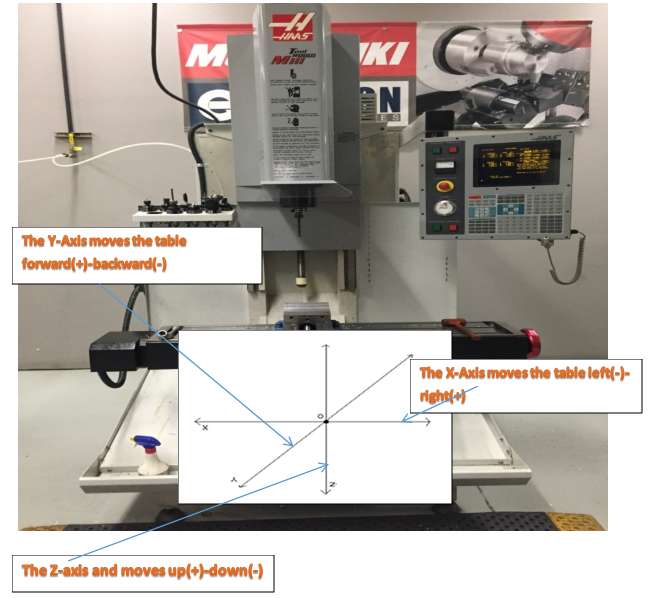

CNC machines use a 3D Cartesian coordinate system. Figure 1. shows a typical Vertical Milling Center (VMC). Parts to be machined is fastened to the machine table. This table moves in the XY-Plane. As the operator faces the machine, the X-Axis moves the table left-right. The Y-Axis moves the table forward-backward. The machine column grips and spins the tool. The column controls the Z-axis and moves up-down.

Adapted from 1) “Individual Learning Systems.” [circa 1994.] Oregon Department of Education; and 2) “Vertical Milling Center Machine Motion” by LanNguen Virasak, Manufacturing Processes 4-5, Open Oregon Educational Resources is licensed under CC BY-SA 4.0