S, T, M03, M04, M06

The information below supports Lesson 1 pages 5-7.

OBJECTIVE

After completing this unit, you should be able to:

- recognize tool numbers

- understand code to change tool

- calculate the spindle speed RPM for milling

- turn on a spindle in the proper direction

Letter Code: Spindle Speed (S)

The letter S is used to set variables related to the spindle. S represents the spindle, and depending on various other settings, can represent the speed of the spindle in revolutions per minute, or the surface speed in a distance per minute. The S code does not start the spindle. It needs an M code (M03 or M04) to start the spindle.

Calculating Speed

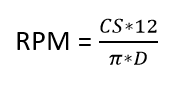

Let’s review the long formula for cutting speed.

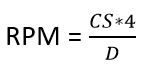

For the manual machines, we do not operate them with calculated speeds. We must set our machines based on selected speeds listed on the machine tool. We can abbreviate this long formula into a short formula. We do this by dividing 12 in the numerator by pi in the denominator. We can use an approximate number because we set the manual machines with selected speeds. We cannot use the exact speed we calculate for. We have used the short formula for manual machines.

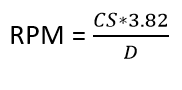

With CNC machine tools, we input a Speed code with exact values of calculated speed. We can still abbreviate or reduce the Long Formula by, again, dividing 12 by pi. We use the more exact answer of 3.82 for our Speed calculations for CNC machines.

NOTE about Speed and Feed Charts!

Be sure to use Speed and Feed Chart for CNC machines. The speeds will be different with manual machines.

Use the correct chart for the correct machine tool!

Letter Code: Tool (T)

The letter T is used to set variables related to the tool. T is the address for a particular tool number. The T address does not initiate a tool change itself. The M code (M06) to changes the tool.

M-Codes for the Spindle (M03 & M04) and Tool (M06)

The Letter codes of S and T inform the computer that the machine needs to do something with the speed or tool. The computer needs to tell the controller what the machine tool needs to do.

The M Codes are used for this purpose.

M03 tells the computer to tell the controller to tell the machine tool to turn on the spindle in a clockwise (CW) direction.

M04 turns the spindle on in the opposite direction of counter clockwise (CCW).

To change the tool, the machine tool will access the tool number with the T# command.

M06 directs the machine tool to change the tool. It might be called a “tool changer” sometimes.

Questions

Adapted from “CNC Language and Structure “ by LamNgeun Virasak, Manufacturing Processes 4-5 is licensed under CC BY-SA 4.0