Linear and Linear Interpolation

Code Practice

Terminology

- A CNC machine move refers to the tool path. What is moving? It’s the tool on the tool path. In this section, you will see both of these terms used to refer to the movement of the CNC machine tool.

- Interpolation: This is a very technical word. It comes from a Latin word which originally meant to polish. However, in English, this word is used to say that something is added. In CNC, the machine needs to move the tool between two points. The computer calculates all of the measurements between the two points. This calculation is approximately the idea of “adding something in between the two points.” The word interpolation is trying to explain the computer calculations to make the machine tool move from point to point.

- dog leg: an idiom. A line is not straight. It is crooked or bent like the hind (back) leg of a dog. For example, “Slow down. The road has a dogleg up ahead.”

Objectives

- Identify the difference between linear and linear interpolated machine moves

Straight Line Moves aka Point-to-Point Positioning

The CNC machine moves point-to-point. The tool is at one point. Then it moves to another point. That’s the easy part. How the machine moves is the topic of this section.

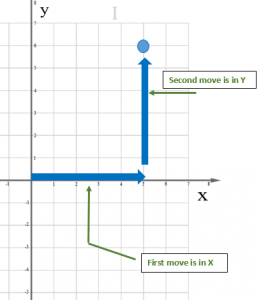

Single-Axis Linear Movement

The motion of the machine is moving along one axis. The tool path might move in X. Then, Y next. Then, Z. The tool path moves along one axis.

(Single-Axis) Linear Machine Moves in the Code

Let’s consider the following code. (Repeat G code and spacing are used for instructional purposes.)

G00 G54 X5

G00 Y6

G00 is a rapid motion. G54 is the work position on the table. The machine is moving from machine home (identified in the machine coordinate system) to the work coordinates (with code G54).

The axes are listed on three separate lines. The controller will move in each axis separately. First, it will move to the X0 position. Then, it will go to the Y0 position. The X and Y positions will not be combined by the controller to move at the same time.

The real code would like like this:

G00 G54 X5

Y6

G00 and G54 are a modal commands and will stay in operation until they are changed. The two axes are coded on separate lines in the program.

The tool path is moving horizontally and then it moves in the cross-feed direction of Y. You might hear the term, “dog leg” to describe this type of 90º turn.

This discussion is about a milling operation.

This type of machine movement takes more time to move from one place to another by moving one axis at a time. It is moving in each axis one-at-a-time as rapidly as possible.

We do not want to waste time in our CNC code. This is why we are teaching you to put both X and Y coordinates on one line of code.

Linear Interpolation Moves

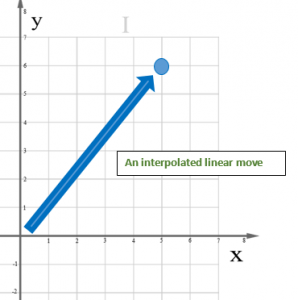

This machine move or tool path will combine X and Y axes to make angular or diagonal lines.

Multi-Axis Linear Movement

A straight line made by the movement of two (or move axes) is an interpolation. The line will be a straight angle.

If the X and Y axes are moving at the same distance, the tool path will be a diagonal line. This is called linear interpolation.

In the next class, we will learn why it is important to understand the tool path a CNC machine will move.

Right now, understand that a linear movement is different than an interpolated linear movement.

Linear Interpolation Move in the Code

Now, let’s check out the following code for differences.

G00 G54 X5 Y6

G00 is a rapid movement. G54 directs the coordinates to the workpiece.

The axes are listed on one line. The CNC controller will calculate the fastest speed for the time and distance each axis must move to insure a perfectly straight and smooth tool movement regardless of the angle. The axes will move at the same time. Sometimes, this movement will result in diagonal motions.

Questions

There is a specific code for linear interpolation, too. We will learn about G01 a little later.

Right now, understand that point-to-point movement is a linear movement that follows one axis. Linear interpolation will move the tool path and make angles by using X and Y axes together.