G76 Threading Cycle

OBJECTIVES

After completing this unit, you should be able to:

- Identify and describe G76 Threading Cycle

- Calculate for K word used in G76

- Calculate for D word used in G76

- Selection number of passes for N word in G76

G76 Threading Cycle

Read this webpage from HAAS about G76 Threading Cycle, Multiple Pass (Group 00).

G76 is the automatic cycle for threading. Remember, the name of these automatic cycles in CNC codes is Canned Cycles.

Variable List:

X = minor diameter, d

Z = length of thread, where D stops

K = radial thread height = (D – d) divided by 2. [K needs a radial value. The difference of diameters is split into two to get the radius.]

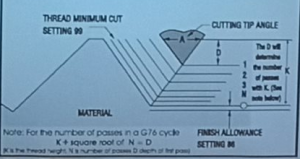

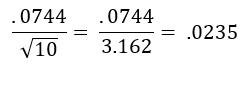

D = Depth of Cut. K is divided by the square root of N; where N is the Number of passes.

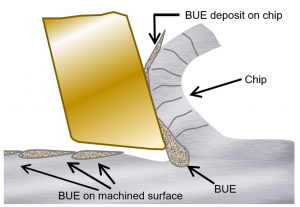

The deeper the cut, the greater the chip load on the cutting tool.

The first cut is shorter and deeper than the final cut.

The final cut is longer and not as deep as the first cut.

The increase in chip load causes Build Up Edge (BUE) on the cutting surface.

How do we determine the N–number of passes–for our calculations?

Look at the thread call out. Identify whether the thread is Coarse or Fine.

- Unified National Coarse (UNC)

- Unified National Fine (UNF)

As an introduction, choose from the following for N.

- Use 10, 12, or 15 passes for coarse threads

- Use 4 or 5 passes on fine threads

F = Pitch

Threading is the last step before we part workpiece off.

Calculation Steps:

|

|

For example:

Step 1: 1 – 8 UNC 2A, 1″ long

Steps 2 & 3: major diameter is .9986. The minor diameter is .8492.

Step 4: X = .8492 (minor diameter)

Step 5: Z = 1.000 (length of thread]

Step 6: K = .9986 – .8492 = .1488. Divide by 2 = .0744

Step 7: This thread is coarse. Let’s choose 10 passes for N.

Step 8: D = .0235

Step 9: F = 1/8 = .125

Z = 1

K = .0744

D = .0235

F = .125

G76 Calculation

Thread Call out: 7/8 – 9 UNC 2A, 1″ long

Single line threading

On printout, the only thing given to you is thread callout

MHB

Look up minor dia

Radial thread height D-d/2

D passes depends on hardneess of material and coarse or fine of thread

e.g.

pic ¾-10 for thread callout

remember 2A is standard

D = .7482 -.7353

Mino: .6255

.005 less than major D

D = .745 Talk about this

It could be average . . . talk about range of Major D

Less amount of thread, rpm slower (under .1000)

Higher thread count, 32, 64, 80 rpm S1500

|

G28 T0303 (60 deg thread) G97 (not max rpm not use CSS) S700 M05 G54 G00 X Less amount of thread, rpm slower (under .1000) Higher thread count, 32, 64, 80 rpm S1500

X2.2, Z1.0 M08 |

Header |

|

Infeed, give cutter a start, need to start off part Need to know major D bring cutter .100 off part X2 for dia of part x.945 Z.2 (give it a little extra space to feed in before it starts to move G76 cycle) G76 X .6255 Z .950 K .0598 D .0173 F .100 For length Z, keep tool off the shoulder. Subtract .050 Length 1” – .050 for Z above K = math This is a big thread Coarse passes, on the final I will give you the number of passes . . . e.g. 12 passes D = practice calculator use Fairly big DOC. F picth 1/20 = .100 |

Body |

|

G00 Z1.0 M09 G28 M05 M30 |

Footer |