G28 Machine Home

Code Vocabulary Practice

Please refer to IMTL-136 textbook, Lesson 4, pg. 2

OBJECTIVE

After completing this unit, you should be able to:

- identify CNC machine coordinates

- recognize where Machine Home is located

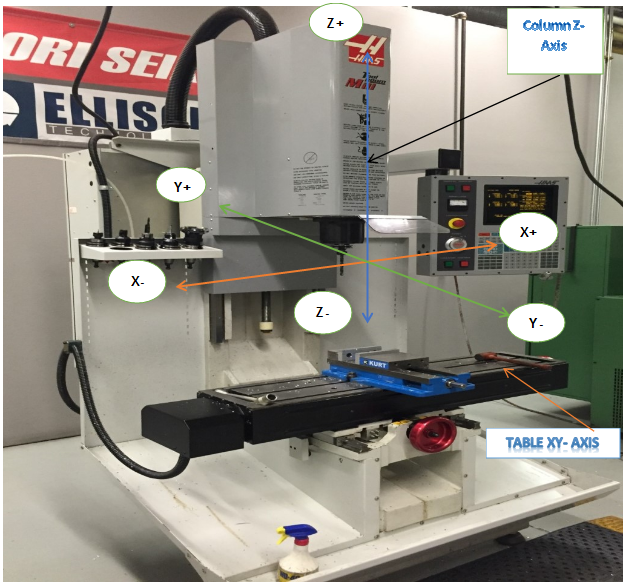

CNC MACHINE COORDINATES

The CNC Machine Coordinate System is illustrated in Figure 1. The control point for the Machine Coordinate System is defined as the center-face of the machine spindle. The Origin point for the machine coordinate system is called Machine Home. The code for Machine Home is G28. This is the position of the center-face of the machine spindle when the Z-axis is fully retracted and the table is moved to its limits near the back-left corner.

As shown in Figure 1, when working with a CNC, always think, work, and write CNC programs in terms of tool motion, not table motion. For example, increasing +X coordinate values move the tool right in relation to the table (though the table actually moves left). Likewise, increasing +Y coordinate values move the tool towards the back of the machine (the table moves towards the operator). Increasing +Z commands move the tool up (away from the table).

ABOUT MACHINE HOME POSITION (G28)

When a CNC machine is first turned on, it does not know where the axes are positioned in the work space. Home position is found by the Power On Restart sequence initiated by the operator by pushing a button on the machine control after turning on the control power.

The Power On Restart sequence simply drives all three axes slowly towards their extreme limits (-X, +Y, +Z). As each axis reaches its mechanical limit, a microswitch is activated. This signals to the control that the home position for that axis is reached. Once all three axes have stopped moving, the machine is said to be “homed”. Machine coordinates are thereafter in relation to this home position.

One of the purposes of the footer in the CNC program is to stop the operation safely. Cutters may be hot as well as very sharp. You are learning to command the CNC machine with the code G28 to move the tool cutter out of the way. G28 sends the tool to machine home. It is very common for the machine home position to be factory set by the manufacturer. However, companies may set machine home to a different location. You will learn this on the job. The machines in the shop are set to the default location of machine home by the manufacturer.

Questions

Let’s learn more about the footer codes to be safe in the next section.

Adapted from “Vertical Milling Center Machine Motion” by LamNgeun Virasak, Manufacturing Processes 4-5 is licensed under CC BY-SA 4.0)