Computer Numerical Control (CNC) Operators

Objectives

- Identify purpose of the control panel on a CNC machine

- Identify information displayed on digital readout panel

- Identify six things a CNC operator needs to know

- Define critical dimensions

- Understand importance of condition of the cutters

- Identify tool numbers

- Understand importance of surface finishes

Vocabulary & Abbreviations

Many companies manufacture Computer Numerical Control (CNC) machines. Each machine is different. Controllers are not the same. The CNC operator learns how to operate the CNC machine in the shop. The operator learns the controls for the machine they are working on.

Questions

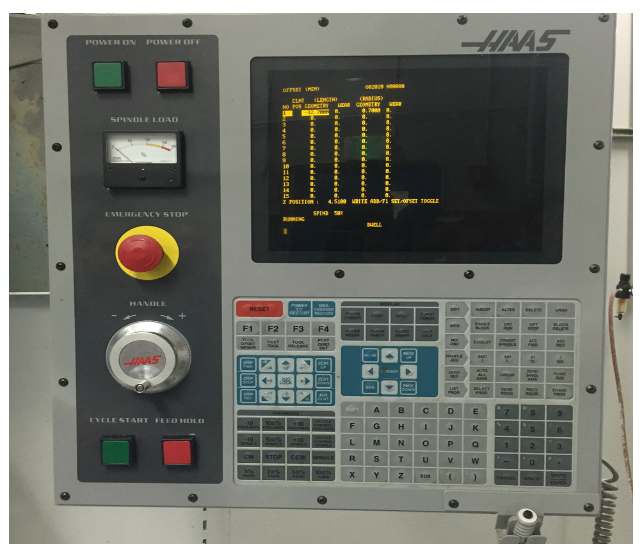

The Control Panel

CNC machines have a control panel. It allows the operator to command or control the CNC machine. The control panel has buttons, knobs, switches, and keys. The operator uses the buttons, knobs, switches, and keys to control the CNC machine tool.

Some of the controls are for:

- starting and stopping

- starting the spindle rotation

- setting the speed rate

- setting the feed rate

- controlling the position of the quill along the Z axis

- selecting the axis

- using a coolant

- changing tools

There are many controls. The machine operator learns about each control on the machine.

Digital Readout Panel

CNC machines have control panels and digital readout (DRO) panels.

Most CNC machine tools have a digital readout display panel. The digital readout tells the CNC operator what the machine is doing. It tells the CNC operator the position of the quill over the part along X, Y, Z axes. For example, a readout might say:

X -1.2218

Y -6.0250

Z 3.000

The CNC operator knows the critical dimensions of the part. The CNC operator watches the digital readout panel to check that the machine is making the part correctly.

Questions

What does the CNC operator need to know?

The CNC operator needs to know:

- The control codes of the specific machine

- The critical dimensions for the part.

These are the most important dimensions. The operator checks the blueprints for the critical dimensions. The operator checks these dimensions on the first part that the CNC machine tool is making. If they are correct, the program is probably correct. If they are incorrect, the CNC operator stops the machine and gets the supervisor to look at the part. The operator gets help before the machine makes many inaccurate parts. - The condition and size of the cutters

If the cutters are dull, broken, or incorrectly sized, the part will not be accurate. The CNC operator uses vernier calipers to check the condition and size of the cutters. - The numbers for the tools and how to load the cutters in the tool carousel or turret.

The manufacture of a part may require several different operations and cutters. The CNC operator knows the numbers for the tools. The operator loads the cutters in the tool holders. Then the tool holders are loaded in the correct order of the operations to be performed. - Loading the program into the machine tool

The CNC operator knows how to load a program into the machine to make a specific part. - Surface finishes

The CNC operator knows about good and bad surface finishes. The operator watches the machine for chattering. Chattering leaves marks on the surface of the part. The operator tells the supervisor right away if the surface finish is not correct.

The CNC operator needs to be alert to any problems with the machine and manufacture of the part. The CNC operator needs to communicate any problems immediately to the supervisor.

Section Questions

- What does the CNC operator use the control panel for?

- What is the digital readout panel for?

- What six things does the CNC operator need to know?

- What does critical dimension mean?

- Why does the CNC operator need to know the critical dimensions?

- Why does the CNC operator need to know the condition of the cutters?

- Why does the CNC operator need to know the tool number?

- Why does the CNC operator need to know about surface finishes?

- What should the CNC operator do if something is going wrong?

Adapted from: “Haas Control” by LanNguen Virasak, Manufacturing Processes 4-5, Open Oregon Educational Resources is licensed under CC BY-SA 4.0