Backlash

OBJECTIVE

After completing this unit, you should be able to:

- understand mechanical backlash in machine operation

- identify backlash mechanism (the ball screw) in CNC machines

Terminology

Backlash: movement in the screw system that operates the slides of a table on a mill or the cross feed on a lathe. An operator turns a handle to move a slide. There is a small amount of movement in the handle where the slide does not move. This is backlash.

With manual machines, backlash is common. The nut and screw have a clearance for their fit. This fit allows for smooth operation. However, the clearance also causes a little movement.

Manual machine operators need to recognize this backlash and turn the handle to remove the backlash. An accessory called a “backlash eliminator” can be used, too.

CNC machines require high precision. They do not require backlash eliminators because the mechanism that moves the slides is different. It is a ball screw.

A ball screw has a threaded shaft and a nut. One part of it is stationary. Either the shaft or the nut can be motionless. Ball screws are similar to ball bearings, where hardened steel balls move along grooves in the shaft. The fit of the balls or the clearance of the balls allows for precise movement.

Ballscrew / Ball Bearing Screw/ Recirculating Ballscrew Mechanism

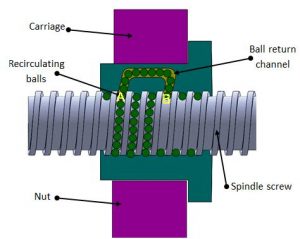

It consists of a screw spindle, a nut, balls and integrated ball return mechanism as shown in Fig. 0.5. The flanged nut is attached to the moving part of CNC machine tool. As the screw rotates, the nut translates the moving part along the guide ways.

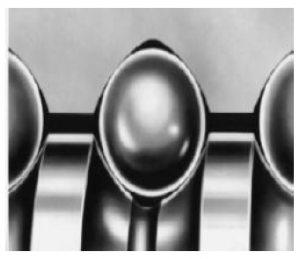

However, since the groove in the ball screw is helical, its steel balls roll along the helical groove, and, then, they may go out of the ball nut unless they are stopped at a certain spot. See Fig. 0.6 for helical groove.

Thus, it is necessary to change their path after they have reached a certain spot by guiding them, one after another, back to their “starting point” (formation of a recirculation path). The recirculation parts play that role.

When the screw shaft is rotating, as shown in Fig. 0.5 ,a steel ball at point (A) travels three turns of screw groove, rolling along the helical grooves of the screw shaft and the ball nut, and eventually reaches point (B).

Then, the ball is forced to change its pathway at the tip of the tube, passing back through the tube, until it finally returns to point(A).

Whenever the nut strokes on the screw shaft, the balls repeat the same recirculation inside the return tube.

Ball screws offer several advantages over other screw types, e.g., acme threads. They are able to move heavy loads rapidly with excellent accuracy. They are cheaper to operate than pneumatic or hydraulic controls for the CNC table slides.

There is no backlash in the CNC machine because the screws that move the slides are different than screws in the manual machines.

Text adapted from (Joshi, 2013)