5 Carbon Steels

Perhaps the moniker “carbon steel” should be replaced with something less misleading because all steel contains carbon. Iron, the basic ingredient of steel, has so much carbon in its pig iron form that carbon actually has to be removed to produce what we call “carbon steel”. So what makes carbon steel different from other steels? One definition for carbon steel is: it must have been refined (high carbon content removed from pig iron) and contain no purposefully added alloying elements other than carbon (for clarity, steel can be produced by reducing the carbon in the pig iron to a level that produces steel OR all of the carbon can be removed and then controlled amounts of carbon put back in).

Residual elements may still be found in carbon steel such as those added for deoxidation or to counter the effects of oxygen and sulphur. In the American Iron and Steel Institute (AISI) standard and the Society of Automotive Engineers (SAE) standard there are % limits placed on the residual elements that may occur in the mix. For example, all steel contains manganese. For some iron ores (like the ore used by the Spartans in ancient Greece) manganese is already in the ore in fairly large quantities. Manganese helps in the refining process to remove unwanted oxygen and sulphur. If the ore is lacking in manganese, then manganese is usually added in the steel making process. However for AISI/SAE designation of carbon steel there is a limit as to the amount of manganese that can be present.. Just remember that carbon steel has carbon as the primary additional element and has no intentionally mixed alloys included to change the mechanical properties of the steel.

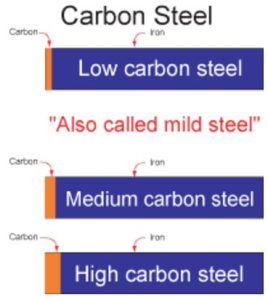

There are hundreds of types of carbon steel each with their own unique characteristics. Presented below are four common carbon steels that are familiar to most machinists (note how the percentage of carbon effects the uses and properties of the steel).

G10100 (AISI/SAE 1010)

- Carbon less than 0.10%

- Machinability good

- Hardenability case harden only

- Weldability good by all techniques.

- Applications screws, bolts, and other cold headed products

- Comments a general-purpose steel that is low in strength unless quenched and tempered

G10180 (AISI/SAE1018)

- Carbon 0.15 to 0.20%

- Machinability medium plus

- Hadenability case harden to RC 42 if less than 4″ thick

- Weldability good by most techniques

- Applications wide variety

- Comments easy to machine, nice finish, great mechanical properties – a good all-around steel that is available in many cold rolled sizes. A nice steel for fixturing with welded risers and gussets. This carbon steel is probably the most common in the machine shop.

G10300 (AISI/SAE 1030)

- Carbon 0.25 to 0.30%

- Machinability good

- Hardenability good with water quenching

- Weldability good by all methods but requires preheating for large sections.

- Applications machinery parts that require strength and hardness

- Comments a good, strong, machinable, steel that is available from all suppliers and in most shapes

G10400 (AISI/SAE 1040)

- Carbon 0.35 to 0.45%

- Machinability medium plus

- Hadenability very good with water quenching

- Weldability good by all methods but requires pre/post heating for large sections

- Applications crankshafts, heavy duty couplings, and cold headed parts

- Comments a good, strong, machinable, steel that is available from all suppliers and in most shapes. It work hardens rather vigorously so sharp cutters and lots of coolant is a must

Why should a machinist care about weldability of the metal? The answer to this question may not be too obvious. The reason is that there are many times when a tooling fixture must be designed and built in the shop. Welding risers and gussets into an assembly is usually faster than trying to machine, screw, dowel, and assemble each of them. Therefore, the machinist/engineer must select a steel that is strong, weldable, can be stress relieved, and is easy to machine after welding. Knowing the weldability of steel is sometimes just as important as knowing its hardness, and machinability.

The following are general vocabulary terms used in the machine shop to define particular groups of steel. They are important terms and should be completely understood.

Use these glossary links to examine and understand their meanings.

- Hot rolled steel

- Cold rolled steel

- Mild steel

Vocabulary note:

The percentage of carbon in steel is often referred to in terms of “points”.

For example, a steel with 0.70% carbon is said to contain 70 points of carbon. R.S. (The Virtual Machine Shop 2011)

Derived from Wikipedia (https://en.wikipedia.org/wiki/Alloy_steel) accessed and available online 13 January 2024 and The Virtual Machine Shop (http://jjjtrain.com/3engineering/7eng_metalsl_hist/eng_metal_hist_01.html) accessed and available 13 January 2024.