28 Microindentation Testing

Scratch tests at low loads were used before the development of microhardness testers using traditional indenters. In 1925, Smith and Sandland of the UK developed an indentation test that employed a square-based pyramidal indenter made from diamond. They chose the pyramidal shape with an angle of 136° between opposite faces in order to obtain hardness numbers that would be as close as possible to Brinell hardness numbers for the specimen.

The term microhardness has been widely employed in the literature to describe the hardness testing of materials with low applied loads. A more precise term is microindentation hardness testing. In microindentation hardness testing, a diamond indenter of specific geometry is impressed into the surface of the test specimen using a known applied force (commonly called a “load” or “test load”) of 1 to 1000 gram force (gf). Microindentation tests typically have forces of 2 Newton units (N) (roughly 200 gf) and produce indentations of about 50 micrometres (μm). Due to their specificity, microhardness testing can be used to observe changes in hardness on the microscopic scale. Unfortunately, it is difficult to standardize microhardness measurements; it has been found that the microhardness of almost any material is higher than its macrohardness. Additionally, microhardness values vary with load and work-hardening effects of materials. The two most commonly used microhardness tests are tests that also can be applied with heavier loads as macroindentation tests:

- Vickers hardness test (HV)

- Knoop hardness test (HK)

In microindentation testing, the hardness number is based on measurements made of the indent formed in the surface of the test specimen. The hardness number is based on the applied force divided by the surface area of the indent itself, giving hardness units in kgf/mm². Microindentation hardness testing can be done using Vickers as well as Knoop indenters. For the Vickers test, both the diagonals are measured, and the average value is used to compute the Vickers pyramid number. In the Knoop test, only the longer diagonal is measured, and the Knoop hardness is calculated based on the projected area of the indent divided by the applied force, also giving test units in kgf/mm².

The Vickers microindentation test is carried out in a similar manner welling to the Vickers macroindentation tests, using the same pyramid. The Knoop test uses an elongated pyramid to indent material samples. This elongated pyramid creates a shallow impression, which is beneficial for measuring the hardness of brittle materials or thin components.

- For any given load, the hardness increases rapidly at low diagonal lengths, with the effect becoming more pronounced as the load decreases. Thus at low loads, small measurement errors will produce large hardness deviations. Thus one should always use the highest possible load in any test. Also, in the vertical portion of the curves, small measurement errors will produce large hardness deviations.

- Vickers

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test has a great advantage of using one hardness scale to test all materials. The first reference to the Vickers indenter with low loads was made in the annual report of the UK’s National Physical Laboratory in 1932.

The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness.

The basic principle, as with all common measures of hardness, is to observe a material’s ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH).

Videos

Watch this 2:12 video Vickers Hardness Test by Labor Werkstoffkunde by Prof. Calles, April 19, 2022.

Watch this 0:42 animated video Vickers Hardness Test by INNOVATEST Europe BV, November 14, 2019.

Knoop

The Knoop hardness test /kəˈnuːp/ is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes.

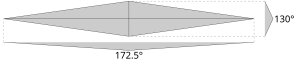

A pyramidal diamond point is pressed into the polished surface of the test material with a known (often 100 g) load, for a specified dwell time, and the resulting indentation is measured using a microscope. The geometry of this indenter is an extended pyramid with the length to width ratio being 7:1 and respective face angles are 172 degrees for the long edge and 130 degrees for the short edge.

The depth of the indentation can be approximated as 1/30 of the long dimension.

Videos

Watch: 1:41 video Microhardness Testing (Vickers and Knoop Test) at Laboratory Testing Inc. , March 19, 2012.

Watch this 0:49 informational video Knoop Vs Vickers by nur ayuni, April 3, 2019.

Derived from Indentation hardness – Wikipedia, Vickers hardness test – Wikipedia, and Knoop hardness test – Wikipedia, accessed and available online 30 January 2024, 23 January 2024, and 23 January 2024, respectively.