53 Brass

Brass, like bronze, is a copper alloy but has a primary alloying element of zinc instead of tin. Zinc alloying of copper to produce brass had been around since the discovery of bronze. However, it was not as easy to produce brass and therefore was not as commonly used.

Over the last few centuries, the alloying of copper-tin and copper-zinc with other elements has become so nearly alike, and the results so similar, that today there are very few functional differences between bronze and brass. Generally, whatever you can be accomplished with a particular bronze alloy can be accomplished with some other kind of brass alloy and vice versa. However, there is one significant difference worth mentioning. Brass, when polished, looks like gold but bronze does not polish as nicely. So, brass has more decorative uses than bronze and – throughout history – has been used this way.

Video

Watch this 5:33 video Making Brass from Scrap Copper and Zinc at our Foundry by mbmmllc, May 7, 2019.

The two primary brasses of interest are those called by their color because the hue of the metals distinguishes it from its siblings. Red brass contains has less zinc (more copper) and yellow brass contains more zinc (less copper). It is not uncommon for the seasoned machinist to request this copper alloy simply by stating its color: “Red Brass” or “Yellow Brass”

C36000

- Primary alloy Lead

- Machinability the best of the brass family

Example of a C36000 part. Source: The Virtual Machine Shop (2011) CC BY-SA 4.0 - Weldability soldering and brazing

- Applications screw machine products

- Comments the most free machining of all metals. The standard by which all brass machinability is judged.

C35300

- Primary alloy lead

- Machinability almost as good as C3600

- Weldability soldering and brazing

- Applications screw machine products, hose fittings, lock parts.

- Comments less free machining than C3600 but more formable for forgings, cold heading, etc.

C35300

- Primary alloy iron

Example of a C35300 part. Source: The Virtual Machine Shop (2011) CC BY-SA 4.0 - Machinability poor for brass

- Weldability soldering and brazing

- Applications electrical hardware, fasteners, fittings

- Comments a cold form brass that is machined after heading.

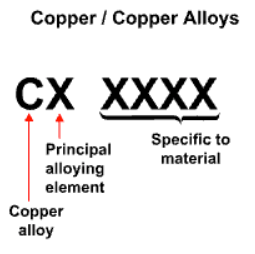

Copper alloys are designated by UNS as CXXXXX as shown:

Brass (left) is an alloy of Copper and Zinc (5 to 45%), it increases strength and hardness but is less resistant to stress corrosion cracking.

Bronze is an alloy of copper and tin. It is more expensive than brass, but its corrosion resistance, strength, and fatigue resistance is better.

The UNS designation system is straightforward. The copper designator is the letter C followed by five digits.

The Key to the UNS Copper Numbering System

- If the first digit is “1” as in C1xxxx then this designates pure wrought copper

- If the second digit is “0” through “5” as in C10xxx through C15xxx then this designates pure wrought copper with no alloys

- If the second digit is “6” through “9” as in C16xxx through C19xxx then this designates wrought copper with alloys in very small amounts

- If the first digit is “2” as in C2xxxx then this designates yellow brass (heavy in zinc)

- If the first digit is “3” as in C3xxxx then this designates leaded brass (zinc with lead)

- If the first digit is “4” as in C4xxxx then this designates tin brass (mostly zinc with some tin)

- If the first digit is “5” as in C5xxxx then

- If the second digit is “0” through “2” as in C50xxx through C52xxx then this designates phosphor bronze (phosphor with tin)

- If the second digit is “3” or “4” as in C53xxx or C54xxx then this designates leaded phosphor bronze (tin, lead, and phosphor)

- If the first digit is “6” as in C6xxx then this designates aluminum bronze (aluminum and tin)

There are many more brasses and bronzes but the above listed should serve the machinist’s needs well enough. One important thing to remember is C2, C3, and C4 is brass. C5 and C6 is bronze.

Videos

Watch this silent video of a flow chart Copper, Brass & Bronze alloys explained by AalcoMetals, October 10, 2013.

Derived from The Virtual Machine Shop at http://www.jjjtrain.com/vms/eng_metal_stds/eng_metal_stds_07.html retrieved from the Wayback Machine 16 January 2024.